Vertical scaffolding

Vertical scaffolding is essential for construction, maintenance, and other high-access tasks. This guide covers everything you need to know about vertical scaffolding, from its components and installation to safety tips and purchasing advice.

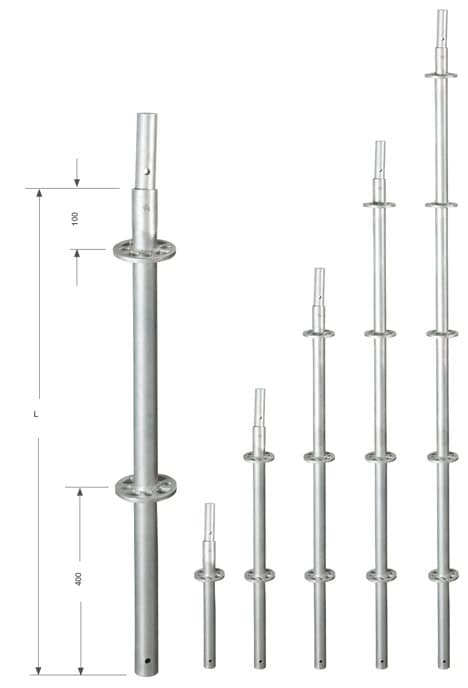

High-Quality Adjustable Shoring Posts

Vertical scaffolding is an essential temporary structure used across construction, maintenance, and repair projects, providing a secure platform for workers to access elevated areas. This system is composed of upright poles (standards) connected by horizontal bars and platforms, forming a stable working environment. Various types of vertical scaffolding are available, each designed to meet specific project needs:

- Ringlock Scaffolding: Known for its modular design, Ringlock scaffolding uses rings for quick and easy assembly, making it ideal for complex structures.

- Cuplock Scaffolding: With its cup connections, Cuplock scaffolding offers rapid setup and dismantling, providing a versatile option for heavy-duty tasks.

- Frame Scaffolding: Featuring stackable metal frames, this type is simple to use and often employed in light-duty projects like facade work.

- Tube and Coupler Scaffolding: A traditional option that uses steel tubes connected by clamps, offering maximum flexibility to adapt to various structures.

Each type provides unique advantages, including enhanced safety, flexibility, and efficiency, making them suitable for diverse work environments.

At Jumply Scaffolding, we specialize in manufacturing and exporting premium vertical scaffolding systems, including Ringlock and Cuplock scaffolding, tailored to meet your specific project requirements. Our scaffolding solutions are not only durable and safe but also designed for easy assembly, ensuring that your worksite remains efficient and productive.

Vertical scaffolding Specification

| ITEM NO. | MATERIAL | L [m] | WEIGHT APPROX. [kg] |

| RSRS 050 | Q355 48.3 X 3.2mm | 0.5 | 3.09 |

| RSRS 100 | Q355 48.3 X 3.2mm | 1.0 | 5.52 |

| RSRS 150 | Q355 48.3 X 3.2mm | 1.5 | 7.95 |

| RSRS 200 | Q355 48.3 X 3.2mm | 2.0 | 10.38 |

| RSRS 250 | Q355 48.3 X 3.2mm | 2.5 | 12.8 |

| RSRS 300 | Q355 48.3 X 3.2mm | 3.0 | 15.23 |

Quality, safety and cost efficiency are our commitments .We are sincere partner to all our clients, irrespective of their sizes. All over the world.

Jumply scaffolding has rich experience and advanced automatic equipment, which can provide scaffolding customized production to meet different needs.

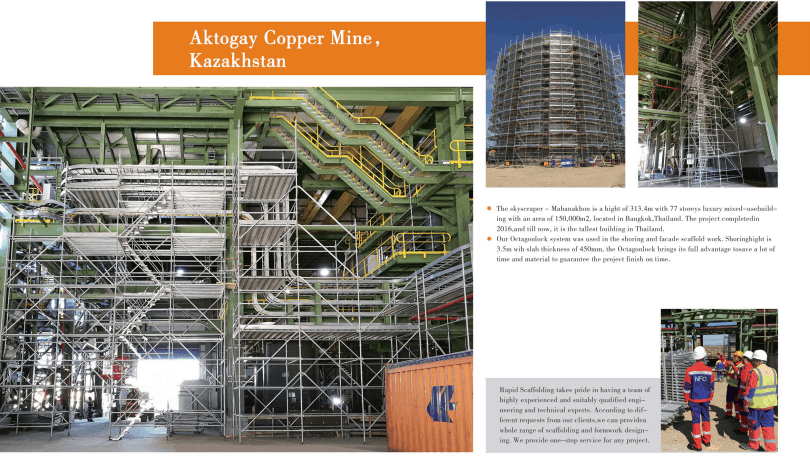

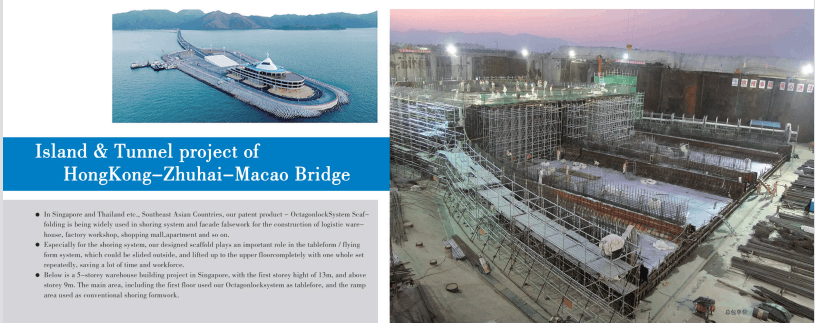

Jumply represent the safety and qualified scaffolding via our construction projects.

Feel the Quality via our products. We improve them always.

Jumply Vertical Scaffolding Video

Why Jumply?

√ More than 20 years experience. Scaffolding Products Quality Warranty

√ Doing construction projects in China and abroad, offer services of the design and customization

√ Own Scaffolding Test House

√ Edited the《China Scaffolding Industry Standard》&《China construction industry standard》

√ CE,ANSI,ISO9001,SGS Certificate

√ All kinds of steel /aluminum scaffoldings

What is Vertical Scaffolding?

Vertical scaffolding is a widely-used scaffolding system designed to offer stable vertical support and safe access for workers operating at various heights. Commonly used in construction, painting, and maintenance, this system consists of upright poles connected by horizontal bars, creating a secure framework for work platforms.

Key Features and Applications of Vertical Scaffolding

- Main Applications: Commonly used in construction, repair, painting, and cleaning tasks at height.

- Advantages: Provides robust vertical support, easily adjustable to various heights, and suitable for both indoor and outdoor use.

- Comparison with Horizontal Scaffolding: Unlike horizontal scaffolding, which extends sideways, vertical scaffolding focuses on vertical reach, making it ideal for taller structures.

Main Components of Vertical Scaffolding

Understanding these components ensures proper assembly and safe usage:

- Vertical Poles (Uprights): The main vertical elements that support the scaffolding’s load.

- Horizontal Bars (Ledgers): These bars connect vertical poles, providing horizontal stability.

- Couplers and Connectors: Securely join poles and bars, maintaining the integrity of the structure.

- Planks: The working platforms, often made of steel, aluminum, or wood, designed to support workers safely.

- Safety Equipment: Essential items like guardrails, toe boards, and safety nets to protect workers.

4. Installation Guide for Vertical Scaffolding

Preparation Steps:

- Site Assessment: Ensure the installation area is level and stable.

- Component Inspection: Check all scaffolding parts for any damage or defects.

- Safety Gear: Ensure all personnel wear appropriate PPE, including helmets, harnesses, and gloves.

Step-by-Step Installation:

- Base Plates: Position the base plates and adjust them for stability.

- Vertical Poles: Set up the vertical poles, securing them with base jacks.

- Horizontal Bars: Attach bars between the poles at designated heights.

- Secure Connections: Use couplers to secure all connections tightly.

- Plank Placement: Lay the planks to create the working platform.

- Safety Installations: Add guardrails and toe boards around the edges.

Key Points: Check all connections regularly and ensure the scaffolding remains level.

5. Safety Tips for Using Vertical Scaffolding

Safety must be prioritized at every stage:

- Installation and Dismantling: Always follow manufacturer guidelines and ensure trained personnel manage the setup.

- Watch for Hazards: Be aware of unstable surfaces, overloaded platforms, and loose connections.

- PPE Requirements: Use helmets, harnesses, and anti-slip footwear.

6. Maintenance and Inspection Tips

Regular maintenance is crucial for scaffolding safety and durability.

Daily Inspection Checklist:

- Inspect connections for looseness or damage.

- Check all safety barriers, such as guardrails and toe boards.

- Confirm that the scaffolding remains level and secure.

Prolonging Scaffolding Lifespan:

- Regularly clean all components to prevent rust and degradation.

- Store equipment in a dry, secure location when not in use.

7. Buying vs. Renting Vertical Scaffolding: Key Considerations

Choose between buying and renting based on project needs:

- Buying: Best for frequent or long-term use, allowing full control over maintenance.

- Renting: Ideal for short-term projects; offers convenience without maintenance responsibilities.

Recommended Brands: Consider reputable suppliers like Layher, PERI, and Safway for high-quality scaffolding.

If you need to know more about vertical scaffolding or get a free quote, please feel free to contact us.

Get A Quote Now !

Frequently Asked Questions (FAQs)

Height limits vary by system and regulations, generally ranging from 6 to 60 feet for standard scaffolding.

Ensure the ground is level, secure all connections, and adhere to load capacity guidelines.

Yes, but it should be properly anchored, and weather conditions must be monitored to maintain safety.