Modular Scaffold

Jumply is a top modular scaffold manufacturer & supplier in China. Modular scaffold, or system scaffold, is a generic term. It consists of a separate part or unit that is used to complete various supports and access works in construction.

We can’t say which one is better, both have advantages and disadvantages when they are in the construction applications. We can design the safer, more efficient application solution according to your requirements.

Since the development of the scaffolding industry, the many system scaffoldings such as ringlock, frame, shoring props, haki, kwikstage, tube and couplers, have emerged.

Jumply offers a variety of system scaffolding, and plank, stair, ladder, beam, transom, guardrail, toe board, couplers, locks, and pins.

In the years of practice, we have comprehensive knowledge of the use characteristics of various modular scaffolding, as well as requirements of materials.

We know what is the best management in the metal manufacturing industry, what are the excellent industrial workers, and how they output the consistently high-quality products in the perfect working environment.

Quality, safety and cost efficiency are our commitments .We are sincere partner to all our clients, irrespective of their sizes. All over the world.

Jumply scaffolding has rich experience and advanced automatic equipment, which can provide scaffolding customized production to meet different needs.

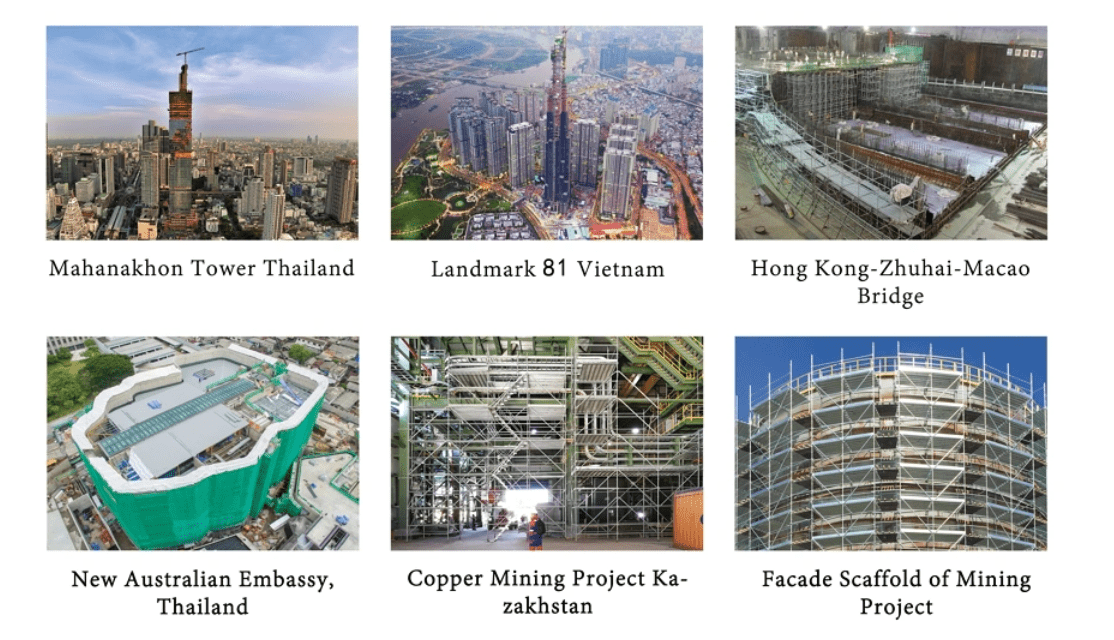

Jumply represent the safety and qualified scaffolding via our construction projects.

Feel the Quality via our products. We improve them always.

Jumply Video

Why Choose Jumply?

- High quality and economical price

- Customized standards for any work site

- Commitment to quality

- Safety and durability

- Innovations in design

- Scaffold services available 24 hours/day

- Gets EN10901 and ISO3834 accreditation

- Certifiedwork-safe scaffolding manufacturer

- Attain quality you need in your work

- Be secure when on the scaffolding

- Provide safety training

- Wide variety of scaffold expertise to suit all needs

- Scaffolds are available in a wide range of sizes

Cuplock Scaffolding

A unique node point connection allows up to 4 horizontal parts to be connected with a vertical part in once single action without the use of nuts, bolts or wedges. The locking device is formed by two cups, a fixed bottom cup which is welded to the vertical pipe at the pre-located intervals and a sliding upper cup. The blade ends of the ledger are located into the lower cup, the upper cup is moved down to secure it in place.

Kwikstage Scaffolding

Kwikstage is a heavy duty modular system scaffold with wedge fixing for all access scaffold requirements. The wedge fixing of the ledgers and transoms gives a simple and fast mean of erecting acecess scaffolding without loose parts.

Ringlock Scaffolding

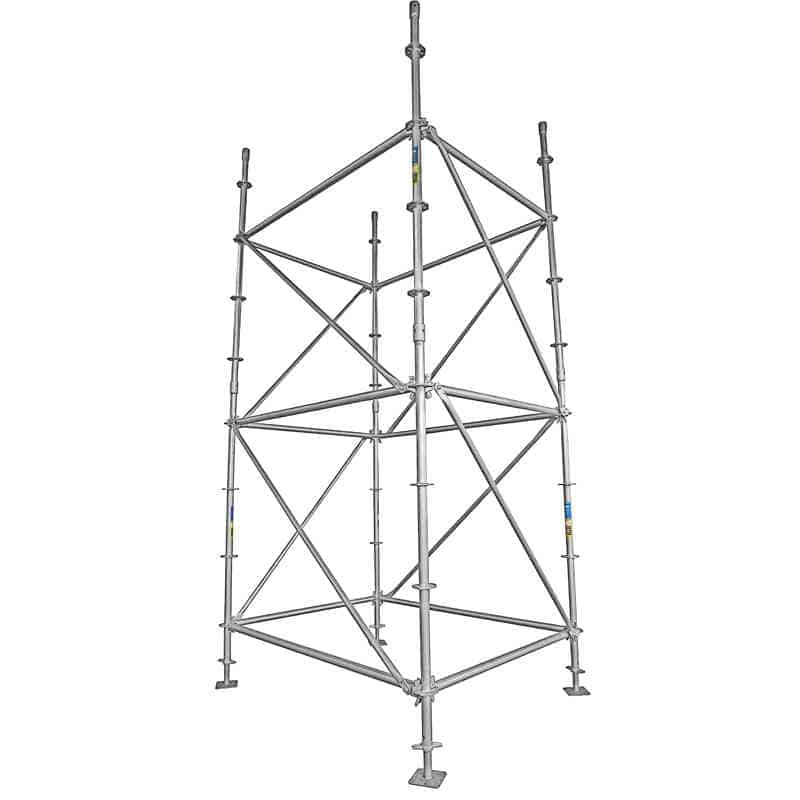

The ringlock scaffolding mainly consists of standard or vertical, ledger, diagonal brace, and components such as base collar, head jack, base jack.

It can be simple and convenient to meet most requirements of temporary structure and access assisted with steel plank and kinds of bracket.

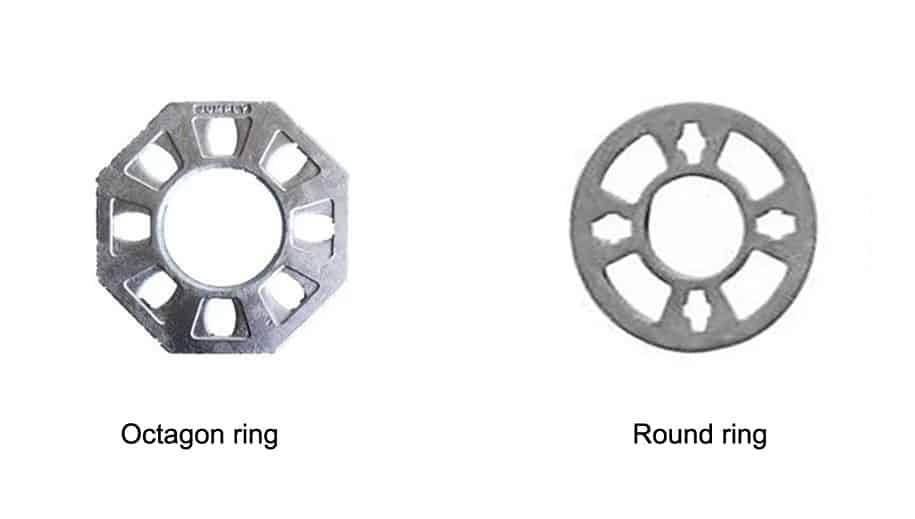

Octagonlock Scaffolding

Octagonlock System – Jumply mother company, Rapid scaffolding patent product, which is developped by our cheif engineer. The ring on the standard is with 8 straight sides, perfectly fits the ledger and diagonal head,which makes the system to be more stable. We made the Chinese National Standard of disk(ring lock system scaffold. Octagonlock is the prototype of this standard.

Haky Scaffolding

Haky Scaffold can save approximately 50% on labour costs than traditional scaffold. Haky Scaffold has fewer components compared to other systems thereby reducing the amount of equipment required to erect,dismantle and transport.

Frame scaffolding

Jumply frame scaffolding belongs to system scaffolding. The frame and cross brace are the main components, so it is named after its shape.

This kind of modular scaffolding may be the most commonly used in construction industry.

Modular Scaffold – The Ultimate FAQ Guide

While there are many different systems of scaffolding in the industry today, modular scaffolding remains to be one of the most promising and cost-effective systems.

But, do you really know what modular scaffolding is? Are you sure and aware of the pros and cons of it? In this guide, we’ll be walking you through understanding what the world thinks about modular scaffolding.

As a bonus, we’ll also give you a few tips on how you can find the best modular manufacturer for your construction needs!

Understanding Modular Scaffolding

Figure 1 – Image of what modular scaffolding is

Don’t be confused, modular scaffolding is also referred to and termed as system scaffolding. So, the next time you encounter it, you’ll know what it is!

It’s a scaffolding system that is primarily made out of horizontal and vertical components that are pre-built and are connected with one another in a systematic and symmetrical order.

Modular scaffolding is known to be the most common and the most used type of scaffolding globally.

To let you know, there are hundreds, even thousands of modular scaffolding manufacturing companies in the world, so you’re not limited to just one (1) option!

What is Modular Scaffolding Used For?

Figure 2 – Modular scaffolding being used for construction

Modular scaffolding is the scaffolding system that’s often used for projects and areas that need space and height. They’re ideal if the operations or the project would be done and accomplished in crowded, small, and compact spaces.

Due to their nature of being symmetrical and space-saving, you’ll find a lot of benefits and pros in using them compared to other systems of scaffolding in the market!

How High Can Scaffolding Go?

The height and the overall length of scaffolding will depend from one region to another. Furthermore, several countries have their own restrictions and limitations when it comes to the height of scaffolding.

In the United States, according to OSHA or the Occupational Safety and Health Administration, the ideal scaffolding system could go higher and above on 125 feet in height. However, that type of scaffolding needs to be designed by a professional and a licensed engineer.

Types of System Scaffolding

System or modular scaffolding is actually divided and categorized into a few different types. These types include, but are not limited to:

Cuplock Scaffolding

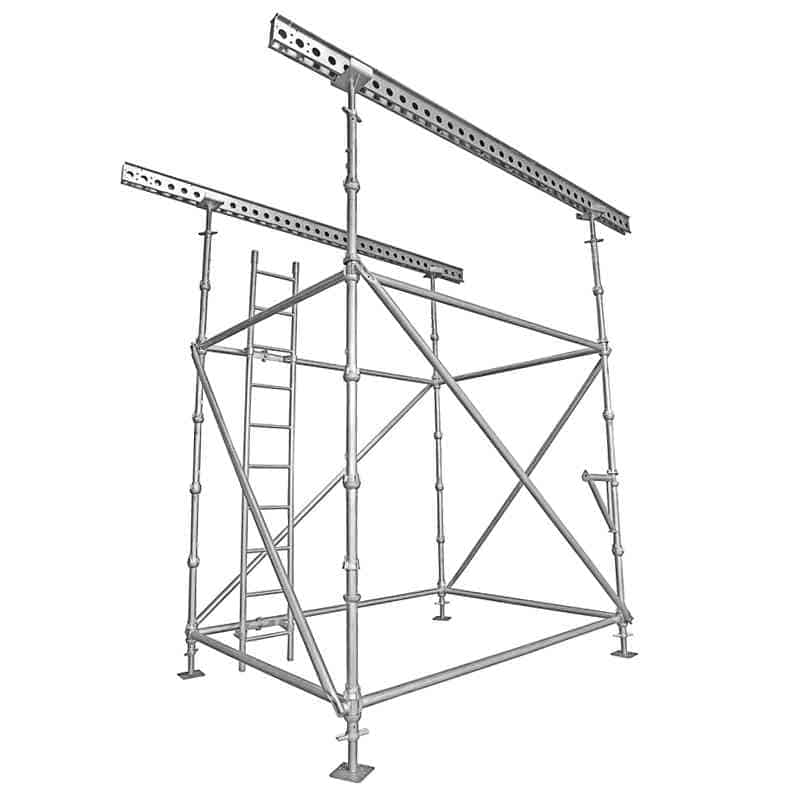

Figure 3 – Cuplock scaffolding example

The type of scaffolding is usually made from galvanized steel. This type is famous and popular for supporting heavy loads with cuplocks at each 500mm to 1,000mm interval.

Ringlock Scaffolding

Figure 4 – Ringlock scaffolding example

Also commonly referred to as haki scaffolding, ringlock scaffolding is commonly utilized in shoring and suspension systems. This is the type of scaffolding that usually is comprised of a vertical ledger, a diagonal brace, and collars, head and base jacks.

Kwikstage Scaffolding

Figure 5 – Sample of Kwikstage scaffolding

One of the more complex and more comprehensive types of modular scaffolds, Kwikstage scaffold is a structure that is complex but is easy to assemble and modify.

It usually just have five (5) components, making it an easy choice. Its five (5) components include:

- Standard and Diagonal Braces

- Staircase

- Base and Head Jack

- Toe Bard

- Ledger

Octagonlock Scaffolding

Figure 6 – Image of an octagonlock scaffold

Last, but most definitely not least is the octagonlock scaffolding. This is the type of modular scaffolding that is comprised of eight (8) standard braces on all sides, which allow the diagonal brace and the ledger to be assembled and fitted in a uniform manner.

These are the types of modular or system scaffolding that you need to know!

What are the Main Different Types of Scaffolding?

The types and kinds of scaffolding are usually updated every now and then. But, there are those that are considered the standard and the most common types of scaffolding in the market.

Wooden or Bamboo Scaffolding

Figure 7 – A worker climbing up a wooden or bamboo scaffolding

This is considered as one of the earliest and the oldest forms of scaffolding in the industry. They’re mainly and primarily used in Asian countries like Hong Kong and China.

Generally, this is the scaffolding type where workers would stand on bamboos or pieces of wood. They’re chosen as one of the most common types of scaffolding because of the fact that they’re sturdy, flexible, and eco-friendly.

Systems or Modular Scaffolding

Figure 8 – Modular or systems scaffolding

This is the type of scaffolding that’s comprised of pre-engineered braces and components and are arranged in such a fashion that they’re symmetrical.

Modular or system scaffolding is the term because the components are “modulated” or “pre-engineered.”

Tube & Clamp Scaffolding

Figure 9 – Traditional scaffolding or tubular scaffolding

Akin to wooden and bamboo scaffolding, tube & clamp scaffolding is also one of the earliest types of scaffolding types made. Its name is derived from the way that it stands and what it has “tube” and “clamps.”

They’re part of the most favorite because they’re simple and easy to use compared to other types of scaffolding. The idea is just the tubes would be tied together using clamps, also known as couplers, and will be made to a height that’s appropriate for the project.

Suspended or Swinging Scaffolding

Figure 10 – Suspended or swinging scaffolding

A lot of experts don’t consider the swinging scaffolding or the suspended scaffolding as one of the types of scaffolding because it’s not built from the ground.

Instead, it’s a plank that’s suspended or that’s swinging and that’s where the workers or the people would be standing.

Frame & Brace Scaffolding

Figure 11 – Frame & Brace scaffolding on an apartment building

Frame & Brace Scaffolding is probably one of the most popular because their idea is simple; they’re just comprised of frames, braces, and bases and is a type of structure that can easily be erected or built.

Do note, though, that compared to system or modular scaffolding, Frame & Brace isn’t as tough and as durable.

These are the types of scaffolding that you will encounter in the market. But, do note, though, that these aren’t the only ones; they’re just the most common and the most popular.

Who needs Modular Scaffold?

Modular scaffolds are extremely versatile and can be used in many different industries for many different types of projects! Whether it’s construction, painting/repairing on the exterior of large buildings, or window-washing on a skyscraper, Modular Scaffold can get the job done.

How do I set up Modular Scaffold?

Setting up Modular Scaffold is easy! The first step is to identify what type of scaffold you need for your project. There are many different types of scaffolds available, so be sure to select the correct one. Once you have the scaffold, it’s important to read and follow all safety instructions for setup and use. Always make sure that the Modular Scaffold is stable before using it!

How do I operate Modular Scaffold?

As with any elevated work platform, it’s extremely important to follow all Modular Scaffold safety procedures. Be sure that the Modular Scaffold is stable and on a flat, solid surface before use! Always wear fall protection gear when setting up or using Modular Scaffold.

Do you need more information about Modular Scaffolds?

Contact us at Modway today for any Modular Scaffold questions! We’ll be happy to answer any you might have.

Modular Scaffold vs. Tubular Scaffold

Figure 12 – Tubular scaffolding is weaker and more prone to discrepancies

Comparing modular scaffold and tubular scaffold is one of the longest-running debates in the industry.

Several experts consider tubular scaffold as the better option, while some consider modular or systems scaffold as the best.

Before we get to the comparison, let us first briefly discuss what tubular scaffolding is.

Tubular scaffolding, otherwise known as classical or traditional scaffolding or tube and clamp scaffolding, is the type of scaffolding where the tubes are going to be conjoined and fused together using clamps or couplers.

With that in mind, you can expect tubular scaffolding to be capable of having a vast range of different positions for further flexibility.

That being said, here are some of the differences between modular scaffold and tubular or traditional scaffold:

Feature | Modular Scaffold | Tubular or Traditional Scaffold |

Cost | Modular scaffolding would regularly be more expensive. However, you can erect and establish it temporarily. | Obviously the cheaper and more affordable option compared to modular scaffolding. |

Safety and Security | Can guarantee safety and security compared to all other types of scaffolding. | Relies on the clamps or couplers to determine the safety. |

Flexibility and Versatility | Flexible and versatile in terms of size. | Flexible and versatile in terms of size. |

Applications | Used in the oil and gas industry, as well as construction. | Used in almost all types of construction and structural project. |

Timing | Quick and easy time to erect and establish. | Usually slower than the normal. |

So, these are the differences and distinctions of modular scaffold from traditional or tubular scaffold.

What is Frame Scaffolding?

Frame scaffolding is one of the types of scaffolding that is comprised of frames or platforms that are supported by end frames with posts, bearings, as well as other components.

Compared to other types of scaffolding, frame scaffolding is seen as the fastest and the easiest to erect. It also does an excellent job of reaching high locations; it’s just that, it’s not as safe as modular or system scaffolding.

What Are the Materials Used For Scaffolding?

Figure 13 – Aluminum steel tubes and bars are things used for it

Traditionally, wood and steel are the materials primarily used for scaffolding. Now, several scaffold manufacturers exhibit the utilization of aluminum, as well as other grades and types of metal as part of the scaffolding.

These are the choices due to the fact that they’re sturdy, durable, and strong when it comes to holding weight.

Scaffolding Parts List

Figure 14 – Parts and components of a scaffold

There are multiple parts and components of scaffolding, and, in fact, it’ll depend on the type of scaffolding you’re after. However, there are a few that are always in the list and they include:

- Standard Braces

- Ledgers

- Scaffold Tubes

- Couplers or Clamps

- Braces

- Base Plates or Platforms

- Toe Boards

- Diagonal Braces

Scaffolding Parts Suppliers

You’ll never run out of options when trying to find scaffolding parts suppliers. In fact, we here at Jumply are more than open to giving you the scaffolding parts and components that you need!

Say, your manufacturer failed to give you everything, we’re just a call away to help and assist you! Jumply will always be prepared to give you the assistance that you’ve been dying to get!

Advantages of Using Modular Scaffold

Some of the advantages and benefits of using modular or system scaffold include:

Safety and Security

Modular scaffold’s primary advantage is that it’s deemed as the safest and most secure type of scaffolding in the market.

Because of how it’s done and finished (symmetrical and in a fashion where it’s pre-engineered), you wouldn’t have to worry about it breaking or falling.

Convenience and Simplicity

It also adds an extra layer of simplicity and convenience to workers because they’re sturdy, tight, and they’re not going to fall off easily.

The space that modular scaffolding offers would definitely be more than what workers would expect.

Versatility and Flexibility

Another primary benefit of it is the fact that it’s available for all the different types of workers. Whether or not a worker has experience, it’ll not be dangerous and risky for them to take on modular scaffolding.

Furthermore, they can also be customized according to your specific needs! You can specify and modify it depending on how you want it to function and look like!

What are the benefits of modular scaffolding over traditional scaffolding?

Modular scaffolds have a number of advantages over traditional scaffolds. They are easier and faster to set up, they take up less space, and they are more stable.

What is a common height for modular scaffolds?

Most modular scaffolds are between seven and ten feet high.

How much does it cost to rent or buy a modular scaffold system?

The cost of renting or buying a modular scaffold system varies depending on the size and type of system that you need.

Which type of material do most people use when they build their own basic platform for construction purposes at home?

Most people choose to use wood as their building material, but some may also use metal or plastic.

Why do some platforms have built-in handrails on both sides, while others only have one side with rails and one without rails?

The purpose of handrails is to provide a safety railing for workers who are using the scaffold. Some platforms have handrails on both sides, while others have them on only one side. It depends on the needs of the individual user.

Where Can You Find High Quality Modular Scaffold?

The world is filled with a ton of modular scaffold manufacturing companies and suppliers. But, if you’re after quality without hurting your budget, you can never go wrong in choosing a Chinese modular scaffolding supplier.

Chinese modular scaffolding suppliers are world-renowned due to the fact that they’re able to produce high-quality parts and components, as well as help you with the installation as well!

Why is Jumply Your Best Choice in Modular Scaffolding?

Across the entire country, Jumply is the modular scaffolding supplier trusted by a wide variety of brands and businesses.

From providing scaffolding parts, to helping with the assembly and the delivery of scaffolding equipment, we got what you need!

Across the entire country, we’re the most trusted and most banked on modular scaffolding manufacturer! We’re not just able to service construction businesses in the country, we can help out construction and structural sites from other regions, too!

Benefits of Choosing Jumply as Your Modular Scaffold Manufacturer

Among the millions of reasons why we’re the best in producing modular scaffold parts and supplies, some of the best ones include:

- We use high-quality and high-grade materials for our modular scaffold

- The delivery time would be within 30 to 45 days sharp

- Jumply can provide samples of the materials for free (small quantity)

- Jumply is a duly-verified and certified manufacturing company

- We’re employed with the country’s top engineers and scaffolding experts

What are you waiting for? Work with us here at Jumply now and enjoy world-class quality modular scaffolding equipment without costing a fortune!

Other than our expertise in modular or system scaffolding, Jumply can also be your best bet if you need aluminum scaffolding, ringlock scaffolding, cuplock scaffolding, scaffolding parts, and many more!

Give us a ring and receive a free quotation for the services and products you need within 24 hours!