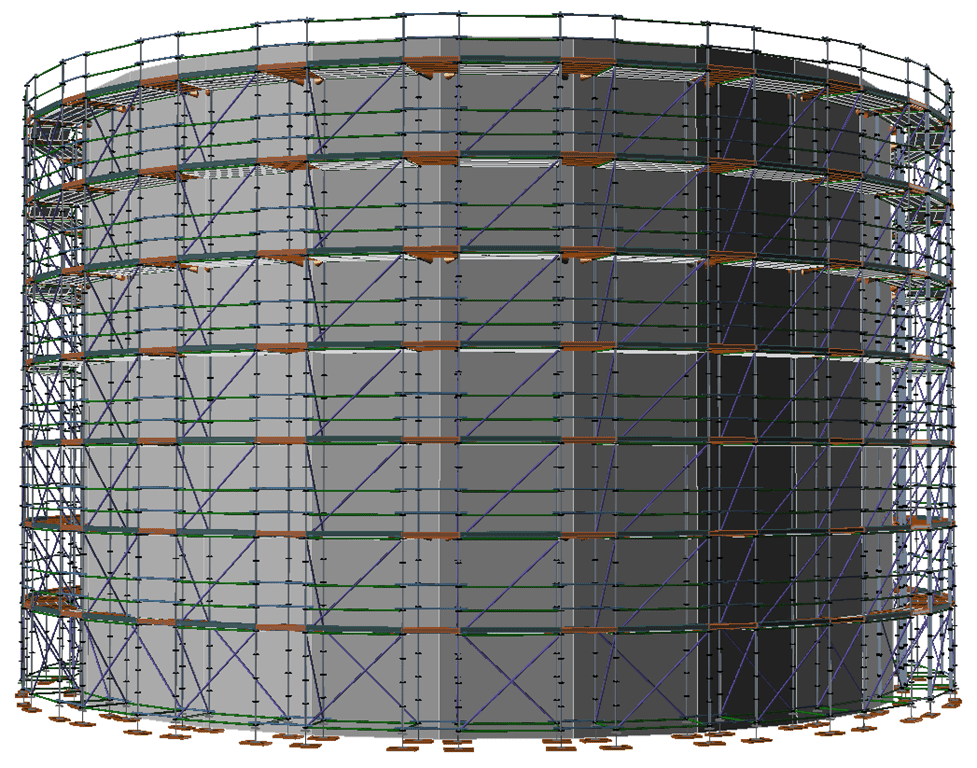

Tank Scaffolding

The tank scaffold is a structure prepared to be installed in all sort of tanks. A tank scaffold can be placed along the boundary of the storage tank or inside it, to perform a maintenance work, all the same, the scaffolding system must be safe and secure as well as ease the job of the drivers operating in the tank.

The first thing you should know about this type of scaffolds is its security; they are made with sets of safety rails (for both sides) attached to two vertical steel tubes which are welded at the top and go down until reaching their respective anchorages at floor level. The various levels will be connected by adjustable horizontal panels equipped with protection rails on every side; these systems are for use by people up to a maximum of 7,5m.

The tank scaffolds are particularly suitable for working in oils, chemicals and other corrosive liquids with the necessary precautions. Other tank scaffold is given bellow:

· Mobile tank towers have bases which can be attached to tank walls or floors. They consist of a slide out deck onto which steel ladder flights are welded at regular intervals along each side.

· Fixed tank towers have decks which are welded on to the top inside surface of the tank wall so that they project beyond the tank circumference when in position. The number of tank tower sections required will depend on tank height and diameter which in turn, determines the overall width of access possible through any one section. Ladders are either fixed to the tank wall or are slung over two wire ropes with snaphooks. A tank tower can have up to three ladders if required.

· Trolley scaffolds are mobile platforms on wheels which provide tank access by means of an overhead bridge beam. They are used where it is not possible to use tank towers or when there is insufficient space within the tank for internal tank towers, e.g.: in drums or narrow-mouthed tanks. The bridge beams consist of a steel I-section horizontally adjustable with support rollers at each end and they can be extended longitudinally by equipping them with suitable telescopic supports. Each trolley scaffold has one set of wheels fitted as standard with a further set of wheels which can be added if required.

· Walkways are simply steel mesh walkways used in conjunction with tank towers or trolley scaffolds to provide safe access up to tank wall height. They consist of a galvanized sheet mesh deck, together with 2 cm diameter stainless steel wire ropes slung over adjustable rollers at each end and fixed into the tank wall by means of secure end plates. The tank tower or trolley is then fitted over the ropes and the platform which provides a man-safe working area from ground level up to tank wall height.

In addition there are various types of tank safety rails available for all tank structures including telescopic type for easy movement / positioning, fixed / adjustable railings and tank wall / ring railings.

To conclude tank scaffold consists of a slide out deck which welded on the inside of tank wall. The tank can be access by means of tank tower or trolley scaffolds and finally, safety rails for tank structures to ensure safe working at height in all sort of tanks.

STORAGE TANK BUILDER SCAFFOLD FOR SALE

Storage tank scaffolding are utilized to shop, a leak or any other damage in the building and construction might seriously harm its material. To execute repair and maintenance services a tank, it is required to accessibility all the locations of the boiler, supporting structures assist us to create an accessibility around the tank, with which we can work in any kind of factor.

Occasionally it is necessary to work with indoor scaffolding Tank. Not all the Tanks are similar, there are various types and capacities, so we need to adjust correctly a supporting framework from inside. We have a home builder team able to generate scaffolds adjusted to every need. If you are working in a tank from inside and you require a scaffold, even if the flooring is straight and not flat, contact us, we can construct scaffolding using tank scaffolding support factors that we find in the within part of the Tank. We make our own pieces individually, as well as we see to it of their top quality. We likewise set up scaffolding safety components that protect against mishaps as well as decrease the repercussions of falls as well as other occurrences. We ensure the high quality of our scaffolding, that’s why all our components have 10 years guarantee on each design.

Our job has actually been always expert and adjusted to each circumstance. Many of our scaffolding is made of aluminum, nonetheless, for tanks with exceptionally harmful materials we offer fiberglass scaffolds, which are more secure since they don’t generate sparks or conduct electrical energy. If you have to perform maintenance work on a tank with a harmful tons, fiberglass scaffolding is the most safe alternative.

In Jumply we are the best suppliers of sale as well as rental scaffolding.

Not all the Tanks are similar, there are various kinds as well as capabilities, so we have to adjust appropriately a supporting structure from within. Most of our scaffolding is made of aluminum, nevertheless, for Tanks with exceptionally dangerous compounds we use fiberglass scaffolds, which are more secure because they do not create stimulates or carry out electrical energy. If you have to execute upkeep job on a tank with an unsafe load, fiberglass scaffolding is the safest choice.