Scaffolding for Building Construction

Scaffolding for Building Construction

The Scaffolding for Building Construction is an essential part of the construction process. Scaffolding provides a safe and secure place where workers can work at heights, while protecting them from falling off the building. Scaffoldings range in size, complexity and function depending on what kind of project they are being used for. This article will focus on some different types of scaffolding you might be interested in using when constructing your next skyscraper.

Building Scaffolding:

This type of scaffolding is used when constructing buildings in urban areas where there are many obstacles that need to be navigated. Building Scaffoldings have a variety of features which increase worker safety and reduce the time it takes to assemble them. Some common types include:

– Bridge Scaffolds:

These scaffolds cross over obstacles like streets and rivers, allowing workers to continue building without having to stop work.

– Scaffold Towers:

These scaffolds are used when there is a lack of space to build traditional scaffolding.

– Rolling Scaffolds:

These scaffolds are wheeled so they can be moved quickly from one area of the building to another.

– Scaffold Gantries:

These scaffolds are used when there is a lack of space for traditional scaffolding and rolling Scaffolds can’t be moved into place.

Bridge Scaffolding:

Bridge Scaffolded structures allow workers to work at heights, while protecting them from falling off the building. Bridge Scaffolds can span large distances and be assembled quickly, making them ideal for large construction projects.

There are a few different types of bridge scaffoldings:

– Tube and Coupler Scaffolds:

These scaffolds use metal tubes to connect the various parts of the scaffold together. This type is popular because it is lightweight, easy to transport and quick to assemble.

– Scaffold Plank Scaffolds:

These scaffolds use wooden planks that are connected by metal couplers or pins at each joint. This type of Scaffolding can be used almost anywhere because the weight limit for Scaffold Planks is about 3000 pounds. Scaffold Plank Scaffolds can be assembled quickly and easily because each plank connects to the next one in a matter of seconds, making these Scaffolding types very popular for large-scale projects.

Screw Drive Scaffold:

Screw drive scaffolds are another type available which consist of steel tubes that connect together with screws. This type of Scaffolding is very sturdy and can be used for heavier loads, making it a popular choice for construction projects that require a lot of heavy lifting.

Scaffold Gantries:

Scaffold gantries are similar to traditional scaffolds, but they have been designed to be as compact as possible. Scaffold gantries are ideal for construction in areas with limited space, because they can easily be stacked on top of one another when not in use.

– XR Scaffolding:

These scaffolds have a grid pattern that allow them to support the weight of workers without needing bulky posts and beams underneath it. This makes these scaffolds very space-efficient and easy to set up in tight spaces.

When choosing a Scaffold for your project, it is important to consider the weight capacity of the scaffold, as well as its ease of transportation and assembly. It is also important to make sure that the Scaffold you choose meets all safety requirements set forth by the Occupational Safety and Health Administration (OSHA). Scaffolds that do not meet these standards can be hazardous to workers, causing them serious injury or even death.

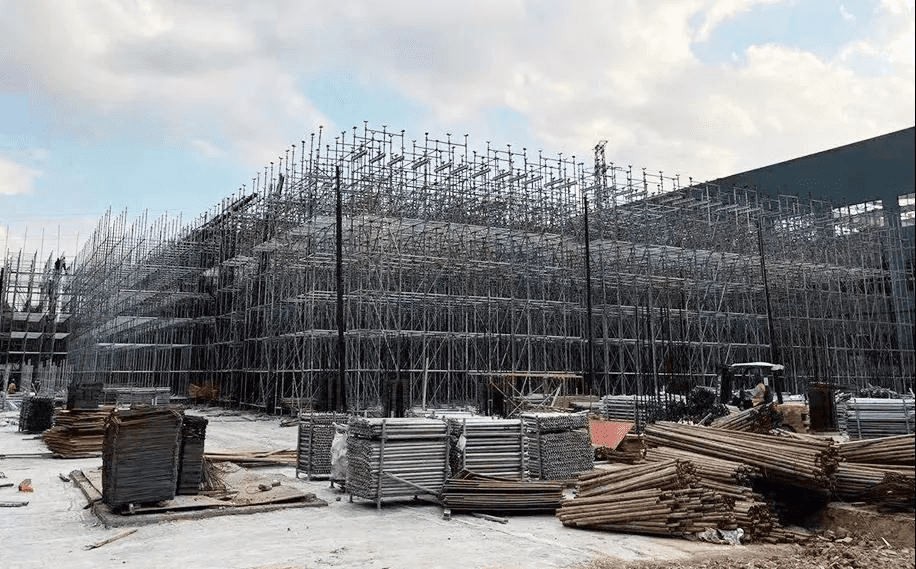

Plant construction experience-Jumply Project Case Sharing

The plant project in this phase is located in the business district of Xidong New City,with a total construction area of 30,375 square meters.Plant area:The construction of concrete beams and slabs adopts the socket type ring lock type support system as the formwork support.

According to the project, the beams with larger beam specifications and more uniform height specifications are all in one direction, and beams in the other direction are all smaller beams. Based on these two points, a unified beam-slab support system is adopted in one direction at the bottom of the beam, and the traditional beam bottom method is adopted in the other direction. The spacing between the vertical bars at the bottom of the beam is 0.9×1.5, 0.9×1.2, 1.2×1.2, 1.2×1.5.

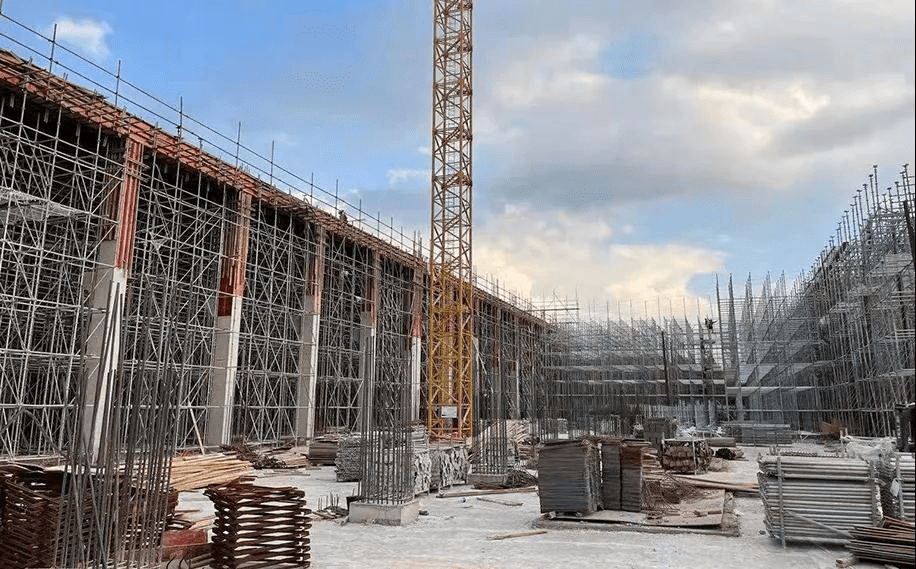

Difficulty 1: There are deep holes with different length and width on the ground.

Solution 1: Erect section steel on the deep pit, set up scaffolding from the section steel, and select the appropriate section steel according to the size of the load.

Difficulty 2: The external frame has been arranged before the ring lock enters the field, so the ring lock needs to change the drawing according to the size of the external frame.

Solution 2: According to the external frame configuration disk buckle frame, in the case of module can not meet the case,disconnect it on the inner side and connect it with a fastener to match the modulus of the beam bottom and the outer frame.

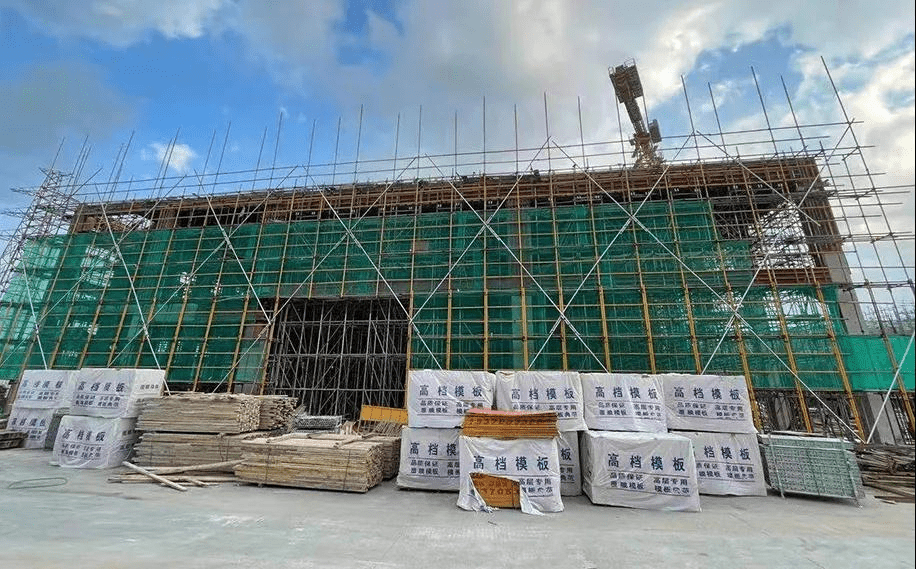

This time, according to the actual situation of the project, combined with the characteristics of the ring lock,make full use of the characteristics of Rapid’s flexible ring lock system.Cooperating with the most suitable plan and technology not only reduces costs for customers but also improves construction efficiency.