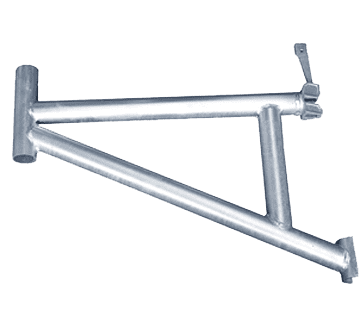

High-Quality Scaffolding Bracket

What is a Scaffolding Bracket?

A scaffolding bracket is a crucial component in scaffolding systems, providing horizontal or vertical support to enhance the stability of the entire structure. It plays a key role in construction projects by allowing workers to safely access various heights, ensuring structural integrity and safety during the project. In modern construction, most scaffolding systems fall under system scaffolding, which includes several types such as Ringlock, Cuplock, and Kwikstage systems, each requiring specialized brackets.

Product Showcase: Scaffolding Brackets for Sale

We offer a wide range of scaffolding brackets for sale, specifically designed to meet the demands of different system scaffolding systems. Whether you’re working with Ringlock, Cuplock, or Kwikstage, we provide high-quality, durable brackets that will ensure the safety and efficiency of your construction projects.

Ringlock Scaffolding Brackets

Designed for high flexibility and strength.

Material: Q235 or Q355 steel

Size: One board: 290mm Two boards: 570mm Three boards: 800mm

Surface Treatment: Hot-dip Galvanized

Cuplock Scaffolding Brackets

Engineered for heavy-duty load-bearing projects.

Material: Q235 steel

Size: One board: 290mm Two boards: 570mm Three boards: 800mm

Surface Treatment: Hot-dip Galvanized or Powder Coated

Kwikstage Scaffolding Brackets

Perfect for fast-paced, time-sensitive projects.

Material: Q235 steel

Size: One board: 290mm Two boards: 570mm Three boards: 800mm

Surface Treatment: Hot-dip Galvanized or Powder Coated

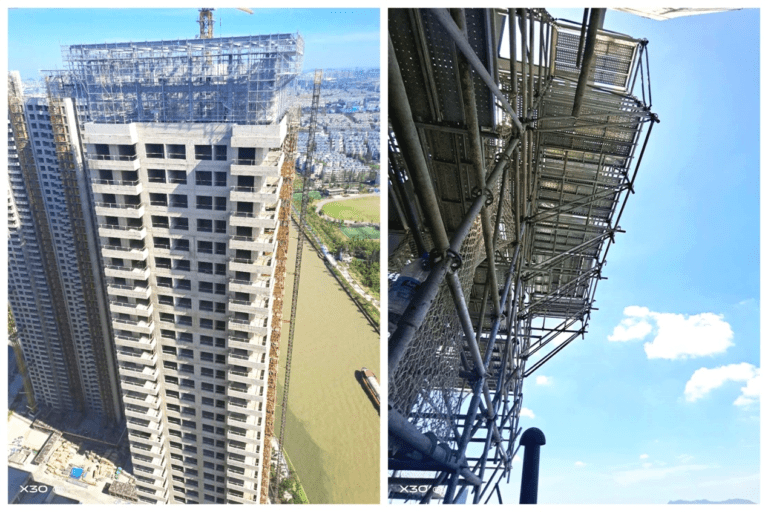

Jumply Scaffolding Bracket Video

Why Jumply?

√ More than 20 years experience. Scaffolding Products Quality Warranty

√ Doing construction projects in China and abroad, offer services of the design and customization

√ Own Scaffolding Test House

√ Edited the《China Scaffolding Industry Standard》&《China construction industry standard》

√ CE,ANSI,ISO9001,SGS Certificate

√ All kinds of steel /aluminum scaffoldings

System Scaffolding Bracket Types

System scaffolding has become the standard in modern construction due to its modular, adaptable, and safe design. The brackets used in these systems vary depending on the type of scaffolding. Let’s take a closer look at the main types of system scaffolding brackets and their specific uses.

1. Ringlock Scaffolding Bracket

Ringlock scaffolding is a highly versatile system known for its unique rosette or “ring” connection points. This system is widely used in projects that require flexible designs and quick assembly. The Ringlock scaffolding bracket is specifically designed to integrate with this system.

Key Features:

Ringlock brackets allow precise and secure connections to the rosettes, ensuring fast setup and teardown. They are typically used to support platforms and provide additional horizontal or vertical stability.Applications:

Commonly used in complex structures like bridges, high-rise buildings, and industrial projects, where flexibility and strength are critical.Keywords:

Ringlock system scaffolding bracket, ringlock scaffolding side bracket, heavy-duty ringlock bracket.

2. Cuplock Scaffolding Bracket

Cuplock scaffolding is another popular system that uses “cup” and “blade” locking mechanisms to create rigid, load-bearing structures. The Cuplock scaffolding bracket is engineered to work with this locking system, ensuring strong, secure connections that can handle heavy loads.

Key Features:

Known for its quick assembly, the Cuplock system is ideal for projects requiring high strength and stability. The brackets are robust and designed for industrial-scale applications.Applications:

Frequently used in large-scale infrastructure projects like bridges, tunnels, and industrial buildings, where high load-bearing capacity is essential.Keywords:

Cuplock system scaffolding bracket, cuplock scaffolding side bracket, cuplock scaffolding support bracket.

3. Kwikstage Scaffolding Bracket

Kwikstage scaffolding is a popular choice for projects that need rapid erection and dismantling. Its wedge-lock design makes it easy to set up without the need for specialized tools. The Kwikstage scaffolding bracket is designed to work seamlessly within this system.

Key Features:

Easy to assemble, Kwikstage brackets provide a secure platform for workers and materials. The system’s modular nature allows for flexibility in a range of construction environments.Applications:

Ideal for residential construction, commercial projects, and temporary structures where time efficiency is a priority.Keywords:

Kwikstage system scaffolding bracket, kwikstage scaffolding side bracket, kwikstage bracket for scaffolding.

How to Choose the Right System Scaffolding Bracket?

When selecting the right scaffolding bracket, it’s essential to consider your project’s specific needs and the compatibility with your scaffolding system. Here are the key factors:

System Compatibility:

Ensure the bracket you choose matches the scaffolding system you’re using, whether it’s Ringlock, Cuplock, or Kwikstage. Each system has its own design, and using incompatible components can compromise safety and stability.Load Capacity:

Different construction projects require scaffolding brackets with varying load capacities. For heavy-duty projects like industrial or large commercial buildings, opt for heavy-duty scaffolding brackets.Material and Durability:

Look for metal scaffolding brackets, typically made from steel or aluminum, as they offer greater strength and longevity, especially in harsh outdoor environments.Application Requirements:

Consider the nature of the project—residential, industrial, or temporary—and choose brackets that are best suited to the scale and requirements of your construction needs.

The Advantages of System Scaffolding Brackets

System scaffolding brackets offer a range of advantages that make them indispensable in modern construction:

Flexibility:

Brackets in Ringlock, Cuplock, and Kwikstage systems are designed to be highly adaptable, allowing for easy customization to fit any construction site, from simple to complex structures.Safety:

These brackets are designed with precision, ensuring that once installed, they provide solid support to scaffolding platforms. This reduces the risk of accidents and enhances worker safety.Modular Design:

The brackets in system scaffolding are modular, which means they can be reused across different projects, saving time and reducing costs associated with scaffolding assembly and dismantling.

By focusing on system scaffolding brackets, we aim to provide our clients with the highest quality products designed for safety, flexibility, and efficiency. If you have any specific questions or need custom scaffolding brackets, feel free to contact us!

Get A Quote Now !

Frequently Asked Questions (FAQs)

Ringlock brackets are used with the Ringlock system, which features rosette connections, allowing for more flexibility and complex designs. Cuplock brackets, on the other hand, use a cup and blade locking mechanism, ideal for projects requiring higher load-bearing capacity.

System scaffolding brackets, whether Ringlock, Cuplock, or Kwikstage, are designed for ease of installation. Most systems can be assembled and disassembled quickly, often without specialized tools, making them efficient and user-friendly.

The best way to choose the right bracket is to assess the type of scaffolding system you’re using, the load capacity required, and the nature of the project. For large-scale industrial projects, heavy-duty brackets are recommended. For residential or smaller projects, standard brackets may suffice.