Ringlock Scaffolding

Jumply is a reliable Ringlock Scaffolding manufacturer for more than 20 years. All types are customizable in sizes, finishes, and designs to meet your basic needs and standards.

Your Ringlock Scaffolding Supplier form China

Ringlock scaffolding is a modular scaffolding system used in a wide range of construction and industrial applications. Its main feature is the use of ring lock connectors to quickly link uprights, ledgers and diagonal braces together to form a solid three-dimensional structure. This system has the advantages of quick installation and dismantling, high load capacity and adaptability, and can meet the needs of various complex projects.

Ringlock Scaffold has been widely used in construction sites all over the world. It’s an ideal temporary structure for any height requirement with its high load-bearing capacity.

If you are looking for a scaffolding that is safe, stable and easy to use, our ringlock scaffold will be your best choice.

Engineering Design, Customized Sizes & Competitive Price Save Your Cost & Time.

We have focused our business structure to best serve scaffolding companies and contractors, helping them to grow their businesses.

Passed EN & ISO 9001 certifications. Owning our own factory & testing laboratory and employing several hundred skilled factory workers helps us to remain competitive in the scaffolding market.

Ringlock Scaffolding Compents

Allround ringlock scaffolding standard

Allround ringlock scaffolding ledger

Ringlock diagonal brace

Allround ringlock scaffold doubler ledger

Ringlock ladder bracket

Ringlock side bracket

Ringlock scaffolding stair

Ringlock ladder

Lattice Girder

Allround ringlock scaffolding base collar

Scaffolding base jack

Scaffolding U head screw jack

Allround ringlock scaffolding 228mm width steel plank

Allround ringlock scaffolding 320mm width steel plank

Toe board

Rinlock Wedge

Why Choose Our Ringlock Scaffolding?

Quality, safety and cost efficiency are our commitments .We are sincere partner to all our clients, irrespective of their sizes. All over the world.

Jumply scaffolding has rich experience and advanced automatic equipment, which can provide scaffolding customized production to meet different needs.

Jumply represent the safety and qualified scaffolding via our construction projects.

Feel the Quality via our products. We improve them always.

√ More than 20 years experience. Scaffolding Products Quality Warranty

√ Doing construction projects in China and abroad, offering services of new scaffolding product design and customization

√ Own Scaffolding Test House

√ Edited the《China Scaffolding Industry Standard》&《China construction industry standard》

√ CE,ANSI,ISO9001,SGS Certificate

√ All kinds of steel /aluminum scaffoldings

Specifications

Ringlock Standard

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q355, Surface treatment: Hot dip galvanized

| Product | Length | ||

| Code | Description | Inches | Meters |

| RLS500 | 1 Ring standard w/spigot | 19.69 | 0.5 |

| RLS1000 | 2 Ring standard w/spigot | 39.37 | 1.0 |

| RLS1500 | 3 Ring standard w/spigot | 59.06 | 1.5 |

| RLS2000 | 4 Ring standard w/spigot | 78.74 | 2.0 |

| RLS2500 | 5 Ring standard w/spigot | 98.43 | 2.5 |

| RLS3000 | 6 Ring standard w/spigot | 118.11 | 3.0 |

Ringlock Ledger

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q355 or Q235, Surface treatment: Hot dip galvanized

| Product | Length | ||

| code | description | Inches | Meters |

| RLL073 | 2′-4″ Ledger | 28.82 | 0.73 |

| RLL1090 | 3′-6″ Ledger | 42.83 | 1.09 |

| RLL1290 | 4′-3″ Ledger | 50.63 | 1.29 |

| RLL1570 | 5′-2″ Ledger | 61.88 | 1.57 |

| RLL2070 | 6′-9″ Ledger | 81.5 | 2.07 |

| RLL2570 | 8′-6″ Ledger | 101.3 | 2.57 |

| RLL3070 | 10′-1″ Ledger | 121 | 3.07 |

Ringlock Diagonal Brace

Tube diameter: 48.3mm, thickness: 2.5mm, Steel Grade: Q235, Surface treatment: Hot dip galvanized

| Product | Width | Length | |||

| Code | Description | Inches | Meters | Inches | Meters |

| RLDB2120 | 2′-4″ Diagonal Brace | 28.82 | 0.73 | 78.74 | 2 |

| RLDB2250 | 3′-6″ Diagonal Brace | 42.83 | 1.09 | 78.74 | 2 |

| RLDB2350 | 4′-3″ Diagonal Brace | 50.63 | 1.29 | 78.74 | 2 |

| RLDB2490 | 5′-2″ Diagonal Brace | 61.88 | 1.57 | 78.74 | 2 |

| RLDB2810 | 6′-9″ Diagonal Brace | 81.5 | 2.07 | 78.74 | 2 |

| RLDB3180 | 8′-6″ Diagonal Brace | 101.3 | 2.57 | 78.74 | 2 |

| RLDB3580 | 10′-1″ Diagonal Brace | 121 | 3.07 | 78.74 | 2 |

Ringlock Bridge Ledger

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q235, Surface treatment: Hot dip galvanized

| Product | Length | ||

| code | description | Inches | Meters |

| RLBL1570 | 5′-2″ Bridge Ledger | 61.88 | 1.57 |

| RLBL2070 | 6′-9″ Bridge Ledger | 81.5 | 2.07 |

| RLBL2570 | 8′-6″ Bridge Ledger | 101.3 | 2.57 |

| RLBL3070 | 10′-1″ Bridge Ledger | 121 | 3.07 |

Ringlock Lattice Ggirder

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q235, Surface treatment: Hot dip galvanized

| Product | Length | ||

| code | description | Inches | Meters |

| RLLG1570 | 5′-2″ Lattice Girder | 61.88 | 1.57 |

| RLLG2070 | 6′-9″ Lattice Girder | 81.5 | 2.07 |

| RLLG2570 | 8′-6″ Lattice Girder | 101.3 | 2.57 |

| RLLG3070 | 10′-1″ Lattice Girder | 121 | 3.07 |

| RLLG4140 | 13′-7″ Lattice Girder | 163 | 4.14 |

| RLLG5140 | 16′-10″ Lattice Girder | 202.4 | 5.14 |

| RLLG5141 | 20′-2″ Lattice Girder | 242 | 6.14 |

| RLLG5142 | 25′-3″ Lattice Girder | 303.5 | 7.71 |

Ringlock Board Bracket

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q235, Surface treatment: Hot dip galvanized

| Product | Length | ||

| code | description | Inches | Meters |

| RLBB360 | 1′-2″ Board Bracket | 14.17 | 0.36 |

| RLBB390 | 1′-3″ Board Bracket | 15.35 | 0.39 |

| RLBB730 | 2′-4″ Board Bracket | 28.82 | 0.73 |

| RLBB1090 | 3′-6″ Board Bracket | 42.83 | 1.09 |

Ringlock Base Collar

Tube size: 48.3×3.2mm & 57×2.5mm. Surface treatment: Hot dip galvanized

| Product | Length | ||

| code | description | Inches | Meters |

| RLBC200 | Base Collar | 7.87 | 0.2 |

Ringlock Caster Adapter

| Product | Length | ||

| code | description | Inches | Meters |

| RLCA300 | Caster Adapter | 12.13 | 0.3 |

Ringlock Scaffolding – The Ultimate FAQ and Buying Guide

Being one of the best and most-used types of system scaffolding in the market, ringlock scaffolding has been boasting of its efficiency and effectiveness in various business sectors and industries.

But, are you sure you have the complete idea on what ringlock scaffolding is? Are you aware of the pros and cons of using this type of modular scaffolding?

In this guide, we’ll not only be bringing you the most relevant information about ringlock scaffolding, but we will also guide you in terms of learning where the best place is to get ringlock scaffolding parts, supplies, and components!

What is Ringlock?

Ringlock is a type of mechanical scaffolding that is used in the construction industry. It is made up of a system of interconnected pipes and joints that can be assembled to create a variety of shapes and structures. Ringlock scaffolding is strong and versatile, making it ideal for use in a wide range of applications. It is also relatively easy to set up and take down, which makes it a popular choice for construction projects.

What is Ringlock Scaffolding?

Part of the newer versions of modular or system scaffolding, ringlock scaffolding is a type of modular scaffolding that, from its term, is interlocked using metallic rings.

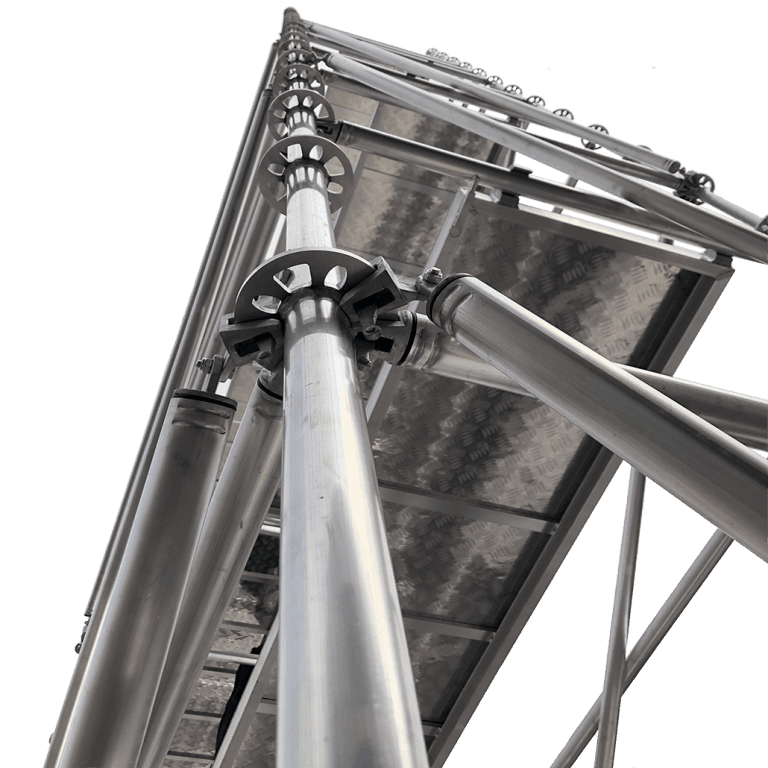

Figure 1 – Image of what a ringlock scaffolding looks like

Also commonly referred to as K-ring scaffolding, it’s the type of modular scaffolding where it doesn’t require a lot of space for storage. It only has a few parts and components.

Compared to other types and kinds of scaffolding, ringlock scaffolding is easy to erect and establish, as well as disassemble.

Ringlock Scaffolding Specifications

Figure 2 – Image of the top of a ringlock scaffolding system

The specifications of the ringlock scaffolding system will differ and vary from one manufacturer to another.

However, the average or median measurements of this particular scaffolding structure include:

- Finish: Galvanized Metal (Hot-Dipped)

- Steel Grade:Q355 Steel

- Approximate Weight:7 KG (on average)

NOTE: This can change and vary widely depending on the type of ringlock scaffolding you’ll be using for your project, as well as the manufacturer of the ringlock scaffolding you’ll be dealing with.

Ringlock Scaffolding Parts

Ringlock is one of the most sophisticated and complete scaffolding systems on the market. It has been designed to keep components minimal to allow for simple set up and dismantle. scaffolding parts are composed of scaffold ring, scaffold lock, and scaffold base.

The ring is the basic working part of ringlock scaffolds. It is inserted into the opening in the top of the upright and locked into place with the scaffold lock. The ring is then used as a hanger for boards or tubes.

There are two types of ring: standard and heavy duty. Standard ring locks have a working load limit (WLL) of 1,000 pounds while the heavy duty ring has a WLL of 2,000 pounds.

The scaffold lock is specifically designed to work with the ring and keep it in place. It is inserted into the keyhole on the ring and turned to lock it into place.

The scaffold base is used to create a stable foundation for the scaffold. It is bolted or clamped to the surface it is attached to.

There are several different types of ringlock scaffolds:

– Basic ringlock scaffold: This is a simple scaffold that is composed of ring, scaffold lock and base

– Heavy duty ringlock scaffold: A ringlock scaffold with a heavy duty ring

– Mobile ringlock scaffold: These types of ring locks are placed on wheels to make them mobile

– Single or double decker ringlocks: One or two decked ring locks that give more working space

– Combined ringlock scaffold: A scaffold that combines ringlock and system scaffold components.

The ring lock scaffolding system is a versatile and durable option for any construction or renovation project. Its simple design makes it easy to set up and take down, and it can be customized to meet the needs of the user. The ring locks are easy to use and very safe.

All ring lock scaffold parts including ring, scaffold lock, and base are available at Jumply!

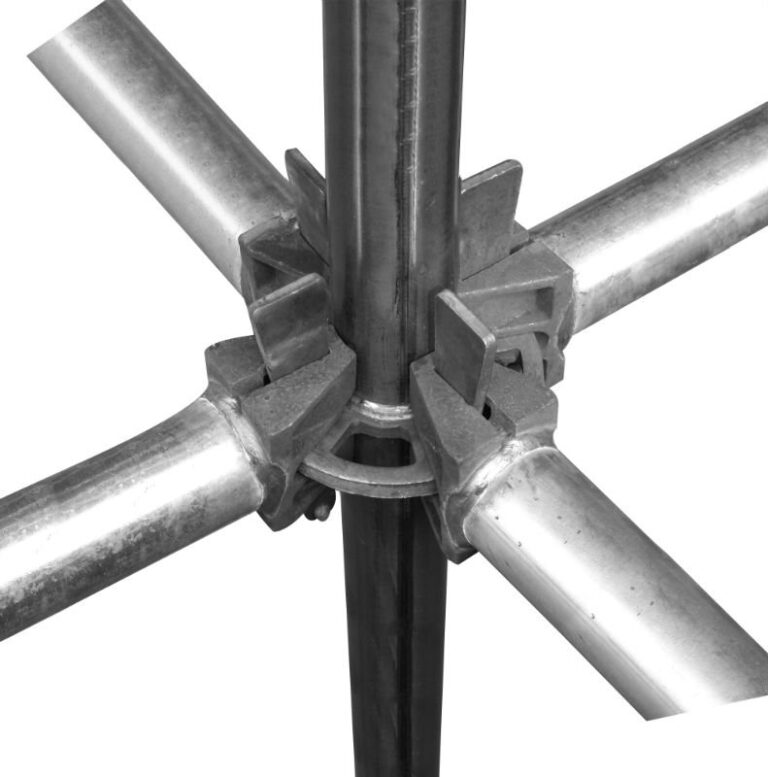

What is a Rosette in Scaffolding?

Rosette clamps are clamps that help in the holding of various parts and components of the scaffolding formwork together.

Figure 3 – A ring or a rosette clamp, which locks the components in place

Also often referred to as ring clamps, rosette clamps help give extra points within a ringlock scaffolding system. They’re popular for their use of making added scaffolding ledgers to connect posts, brackets, and even braces to one another.

Ringlock vs. Cuplock Scaffolding: Know the Difference

Since they’re both comprised of “locks,” how does ringlock scaffolding differ from cuplock scaffolding? What are the distinctive differences and similarities that these two (2) have?

Figure 4 – A zoomed-in cuplock scaffolding system, which is enclosed and locked in via cups

Let’s take a look at some of the factors that differentiate ringlock scaffolding from cuplock scaffolding.

Design Difference

From the term alone, it’ll already be easy to distinguish that part, if not the most different factor between the two (2) would be the design.

Cuplock scaffolding is engineered to have a central node, connecting and attaching two (2) or more pieces of components, whereas ringlock scaffolding is designed to lock-in using rosette-types of points that give the ability to be at certain angles, making the installation and disassembly processes easier.

Central Connecting Points

Ringlock scaffolding can provide a total of eight (8) central connecting points, while cuplock can only give four (4). This simply means that cuplock scaffolding can offer no loose parts, that it’ll be steady and stable to where and how it was installed.

These are some of the most distinctive differences between the two (2) types of system or modular scaffolding.

Ringlock Scaffolding For Sale

Ringlock scaffolding is one of the most popular types of scaffolding you will encounter in the market. That being said, you’ll be able to find a lot of these for sale in the market.

Figure 5 – You’ll be able to find a lot of ringlock scaffolding systems for sale in the market

A simple search would be enough for you to locate what you need; you’ll be able to find a lot of for sale ringlock scaffolding in websites like Alibaba, Made In China, ADTOMall, and many more!

The pro or the benefit of this is that you don’t need to go to a different location to purchase it, you can do it in the comfort of your own home! However, the downside would be the fact that you might not be able to get the exact type of scaffolding you need, since these would already be pre-made.

If you want a custom ringlock scaffolding that perfectly fits what your idea is, work with a ringlock scaffolding manufacturer like us here at Jumply. We can produce the exact specifications that our clients are looking for, regardless of the project or the business sector it’ll be used in.

We will be tackling more of that in the latter part of this guide.

Parts and Components of a Ringlock Scaffolding System

Similar to all other types of modular scaffolding, ringlock scaffolding also has a few parts and components that make up the entirety of the scaffolding formwork.

They include:

- Vertical Post

- Horizontal Ledger

- Ringlock Braces

- Truss Ledgers

- Base Posts/Products

- Brackets

- Planks

- Stair Stringers

- Treads

- Storage Racks and Baskets

- Other Accessories

NOTE: Some ringlock scaffolding manufacturers and suppliers might call or term them differently, but these are what the regular terms are.

Can You Hire or Rent Ringlock Scaffolding?

Figure 6 – Ringlock scaffolding for rent or for hire

Several businesses choose not to invest fully in ringlock scaffolding, which leads them to the confusion of whether or not it’s right to set up scaffolding for their projects.

But, technically, there’s an option to rent or to hire ringlock scaffolding so you wouldn’t have to purchase it.

Yes, you can choose to hire or rent from a ringlock scaffolding manufacturer so long as the manufacturer or the supplier offers it.

What is a Ringlock Ledger?

Figure 7 – Image of what a ringlock ledger looks lke

As part of the components of a ringlock scaffold, a ringlock ledger is a type of connector that fuses or combines various sections of the formwork.

It is the horizontal connector that links interlocking areas or sections of a ringlock scaffolding.

Ringlock Scaffolding Installation

The process of installing and erecting ringlock scaffolding is not far from how regular scaffolding formworks are done.

To help you understand and comprehend it better, here’s a detailed summary of how ringlock scaffolding formworks are installed.

- The base measurements are taken into account and measured.

- After that, the vertical posts are inserted onto the base accessories or products.

- Next, the horizontal ledgers are positioned in accordance to the vertical posts.

- They’re locked in using the clamps, interlocking them with one another.

- Then, the planks are positioned and installed in between the ledgers in order for the installer to be able to stand up on each of the stands to install the next layer.

- The process continues on until it reaches the desired height of the scaffold.

This is the regular or the standard process of how ringlock scaffolding is erected and established. Take note, that not all manufacturers and companies follow this same process; it might differ from one supplier/manufacturer to another.

Who is the Best Ringlock Scaffolding Manufacturer in China?

Here in China, no other ringlock scaffolding is more trusted and relied on as us here at Jumply. For more than a decade, we’ve been providing the most durable, the strongest, and the most sought-after ringlock scaffolding parts, components, and assemblies.

Our expertise allowed us to partner with some of the world’s most popular and most famous construction and engineering companies.

With our help, they never had any troubles or problems with the scaffolding requirement they needed!

Why Should You Work With Jumply For Your Ringlock Scaffolding Needs?

Having years of practice and experience in the industry, Jumply will never fail in producing the best assemblies of ringlock scaffolding to companies, businesses, and enterprises.

Here are some of the most relevant factors on why we’re deemed as the best in the whole of China:

- We exhibit management of metal in the manufacturing sector

- Jumply is equipped with professional and experienced workers and engineers

- Our company can give you assurance that your assemblies will all be complete

- We can design the best, safest, and highest quality of ringlock scaffolding all depending on your wants!

- All of these and more when you decide to go with us for your ringlock scaffolding needs!

With Jumply, the ringlock scaffolding formwork will never fail! All of the businesses that worked with us had nothing but delight and praise to our products and services.

Other than ringlock scaffolding, you can also consider Jumply as your go-to manufacturer for other types of scaffolds, such as cuplock scaffolding, shoring frames, Kwikstage scaffolding, and many more!

Work With Us Today!

Want to be free from the constant stress of where you can get high-quality ringlock scaffolding? Do you want to get the guarantee or the assurance that you will be receiving only the best ringlock scaffolding products and services?

Reach out to us here at Jumply and we will definitely get you what you need!