Frame scaffolding

Jumply frame scaffolding belongs to system scaffolding. The frame and cross brace are the main components, so it is named after its shape.

This kind of modular scaffolding may be the most commonly used in construction industry.

In building construction, decoration, and maintenance projects, you can find that the frame scaffolding with plank, transom, and guardrail is a significant choice among steel facade scaffolding systems.

Jumply Frame Scaffolding Video

Why Jumply?

√ More than 20 years experience. Scaffolding Products Quality Warranty

√ Doing construction projects in China and abroad, offer services of the design and customization

√ Own Scaffolding Test House

√ Edited the《China Scaffolding Industry Standard》&《China construction industry standard》

√ CE,ANSI,ISO9001,SGS Certificate

√ All kinds of steel /aluminum scaffoldings

Our commitment to quality, safety, and cost efficiency sets us apart in the industry. As dedicated partners, we support clients of all sizes worldwide. Whether you need a reliable aluminum ringlock ledger or other scaffolding solutions, we are here to meet your needs with unparalleled expertise and dedication.

Our aluminum ringlock scaffolding systems are not only lightweight and durable but also adhere to the highest safety standards. These features make them the ideal choice for a wide range of construction and industrial projects. We are consistently dedicated to providing top-quality products and services, ensuring your projects proceed smoothly and cost-effectively.

Jumply Scaffolding brings extensive experience and state-of-the-art automated equipment to deliver customized scaffolding solutions, including ringlock ledger systems, tailored to meet diverse requirements.

Jumply stands for safety and quality in scaffolding, showcased through our construction projects. Experience the superior quality of our products, including our ringlock ledger systems, which we continually enhance to meet your needs.

There are three kinds of frame scaffolding in our experience along with our customers, such as American Frame, Euro Frame, and Japanese Frame. There are other specific names of frame scaffolding in this industry, like baker scaffolding that is actually narrow frame scaffolding, if you add caster on it, you can move it easily, known as portable scaffolding or rolling scaffolding in some areas.

Following, we list some common data of frame scaffolding. The frame is made in a wide variety of sizes and configurations, and we can meet customer’s requirements in width, height, OD, thickness, etc. Meanwhile, we also supply the steel and aluminum plank, casters to satisfy customer’s applications.

American Frame Scaffolding

Step Frame

Step Frame, also called Mason Frame

Leg Tube: OD41.2mm, Surface treatment: Powder Coated

Product | Width | Height | |||

Code | Description | Inches | Meters | Inches | Meters |

AFSF01 | 5’*3′ Step Frame | 60 | 1.524 | 36 | 0.914 |

AFSF02 | 5’*4′ Step Frame | 60 | 1.524 | 48 | 1.219 |

AFSF03 | 5’*5′ Step Frame | 60 | 1.524 | 60 | 1.524 |

AFSF04 | 5’*6’4″ Step Frame | 60 | 1.524 | 76 | 1.93 |

Walk Through Frame

Leg Tube: OD41.2mm, Surface treatment: Powder Coated

Product | Width | Height | |||

Code | Description | Inches | Meters | Inches | Meters |

AFWTF01 | 4’*5’7″ Walk Through Frame | 48 | 1.219 | 67 | 1.702 |

AFWTF02 | 4’*6’4″ Walk Through Frame | 48 | 1.219 | 76 | 1.93 |

AFWTF03 | 5’*4′ Walk Through Frame | 60 | 1.524 | 48 | 1219 |

AFWTF04 | 5’*6’4″ Walk Through Frame | 60 | 1.524 | 76 | 1.93 |

AFWTF05 | 5’*6’7″ Walk Through Frame | 60 | 1.524 | 79 | 2.007 |

Ladder Frame

Leg Tube: OD41.2mm, Surface treatment: Powder Coated

Product | Width | Height | |||

Code | Description | Inches | Meters | Inches | Meters |

AFLF01 | 2’*5′ Ladder Frame | 24 | 0.61 | 60 | 1.524 |

AFLF02 | 2’*6’4″ Ladder Frame | 24 | 0.61 | 76 | 1.93 |

AFLF03 | 3’*4′ Ladder Frame | 36 | 0.914 | 48 | 1219 |

AFLF04 | 3’*5′ Ladder Frame | 36 | 0.914 | 60 | 1.524 |

AFLF05 | 3’*6′ Ladder Frame | 36 | 0.914 | 72 | 1.829 |

Japanese Frame Scaffolding

Japanese Frame – 01

Surface treatment: Hot-dip Galvanized

Code | Width | Height |

JF01 | 410mm | 1700mm |

JF02 | 610mm | 1700mm |

Japanese Frame – 02

Surface treatment: Hot-dip Galvanized

Code | Width | Height |

JF03 | 1219mm | 1524mm |

JF04 | 1219mm | 1700mm |

JF05 | 1219mm | 1930mm |

Japanese Frame – 03

Surface treatment: Hot-dip Galvanized

Code | Width | Height |

JF06 | 1219mm | 914mm |

JF07 | 1219mm | 1219mm |

Euro Frame Scaffolding

Euro Assembly Frame

Euro Assembly Frame | ||

FINISH: Hot-dip Galvanized | ||

ITEM NO. | W | H |

RSEF 01 | 2’5”(0.73m) | 3’3”(1.0m ) |

RSEF 02 | 2’5”(0.73m) | 6’7”(2.0m) |

Aluminium Robust Hatch-type | ||

FINISH: Plywood & Aluminum | ||

ITEM NO. | W | L |

RSRH 01 | 0.61m | 2.57m |

RSRH 02 | 0.61m | 3.07m |

Considered as one of the building blocks of all other scaffolding types in the industry, frame scaffolding has been out of the picture because of newer and better scaffolding kinds.

However, it is still seen as one of the simplest, most basic, and yet, most advanced types of frame scaffolding in the industry.

That’s why in this guide, we’ll not only be guiding you in learning what frame scaffolding is, we will also give you the information on how you can find the best frame scaffolding supplier so you can source out the best quality of materials you can!

What is a Frame Scaffolding System?

Also commonly referred to as sectional scaffolding, is one of the most typical types of scaffolding in the residential sector or industry.

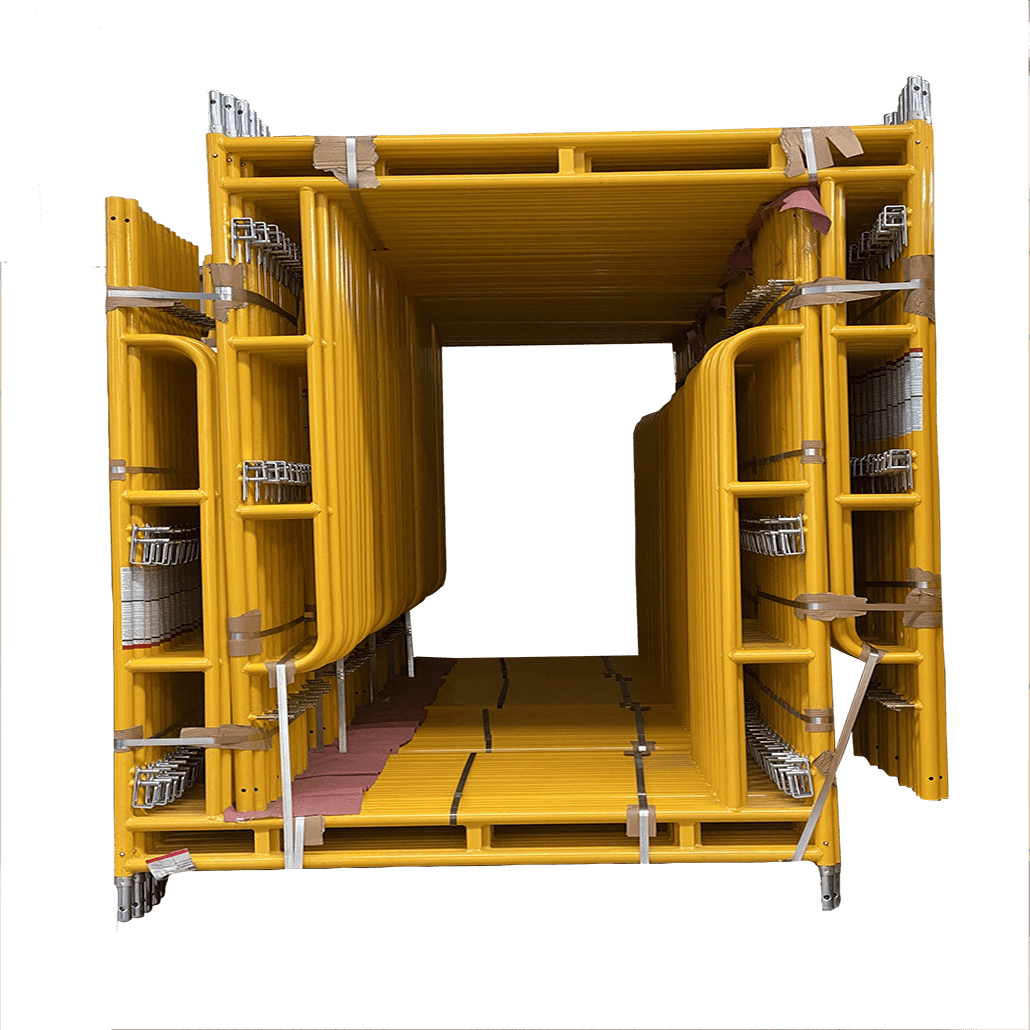

Figure 1 – Image of what an H Frame scaffolding looks like

It’s also used in a couple of commercial jobs in the Americas and Europe, and is known for its simplicity and basic use of frames to support weight at heights more than 10 meters.

This type of scaffold utilizes aluminum frames and braces, as well as welded steel connected and linked by cross braces, forming a framework that’s able supports planks, catwalks, and other types of components.

What Are the Advantages of Using Frame Scaffolding?

Figure 2 – Frame scaffolding is beneficial and advantageous for certain applications

Using frame scaffolding for your business and construction projects can give you a ton of different benefits and advantages.

Some of these advantages include:

- It’s one of the best and most economical scaffolding solutions for various constructions projects

- Assembly and disassembly of frame scaffolding is fast, easy, and convenient

- No moving parts, only governed by poles and rails

- You can assure that it’ll have a large capacity

While these already seem substantial, the pros and advantages of choosing frame scaffolding doesn’t end there. In fact, it’s just the beginning.

You’ll be able to find a lot more pros and benefits when you start to experience it firsthand!

What Are the Disadvantages of Using Frame Scaffolding?

Now that we know all the pros and advantages of frame scaffolding, let us now discuss the cons or the drawbacks of it.

- Frame scaffolding does not offer extreme flexibility, it’s stationary and stable

- The cross supports can easily be broken in the hinge points

- It’s cheap, and therefore, you might have the idea that it wouldn’t be as strong and durable as other scaffolding types

- Compared to others, it’s a bit more requiring in terms of design and engineering

These are the drawbacks and the cons of using frame scaffolding. Of course, all of these can easily be worked and solved, given the fact that you know the ins and outs of the business.

How Do You Install Scaffolding Frames?

The installation of scaffolding frames is considered to be the simplest, the most convenient, and the most usual out of all the different scaffolding types you’ll encounter in the market.

Figure 3 – A worker setting up or establishing a frame scaffolding system

To get you the specifics on how it’s erected and established, it follows these steps:

- Choose to establish it at a secure and reliable foundation.

- Assemble the frames of the scaffolding. Lay the ends out, and then lift one (1) of the end pieces and attach the upper brace.

- While doing this, ensure that the scaffold is stable.

- Depending on the areas you’ll be working on, place and position the planks to their rightful positions.

- Then, secure the access to the scaffold. Use ladders to reach high and far-off places.

- After that, the next step is to attach the guardrails on each of the platforms and layers using the platforms and layers.

- Then, lastly, make a final inspection of the scaffolding to guarantee safety and security. Make a complete and thorough examination of the scaffolding to ensure that all pieces are secured.

This is the standard procedure of how you install frame scaffolding.

H Frame Scaffolding

H Frame scaffolding is a type of frame scaffolding that utilizes H steel frames for the building of the formwork.

Figure 4 – H Frame scaffolding

Just like modular or system scaffolding, frame scaffolding also holds quite a few different types, too.

So, don’t be confused when you encounter H frame scaffolding when you’re shopping for frame scaffolding suppliers and manufacturers.

Frame Scaffolding Parts

Frame scaffolding is one of the simplest and most basic types of scaffolding systems in the market. Therefore, you can expect it not to have a complex set of parts and components.

Figure 5 – An image of the complete parts and components of frame scaffolding

To let you know of them further, here are the parts and components of installing or erecting frame scaffolding.

Base

The base is the foundation of the entire frame scaffolding system. It is the part where everything is built upon and it should be capable of supporting the weight of the people, as well as the materials that would be sent to the scaffold.

Cross Supports

These are the parts and components that connect two (2) or more pieces of frames. They’re the primary source of support and connection of various frames in the formwork.

Hooks

The hooks are the secondary support system of the connecting of frames, bars, and braces in place. They work hand-in-hand with cross supports to further the stability of the scaffolding.

Connecting Rods

The connecting rods are rods that are usually used for the assembly of the fittings, such as the doorframe.

Planks

The planks are the basic blocks of the layers or the platforms of the frame scaffolding. These planks aren’t just limited to wood, they can be steel, plate nets, metal, and even board panels as well.

Frame Scaffolding vs. Tube and Clamp Scaffolding

Many people have the misconception that tube and clamp scaffolding and frame scaffolding are two (2) similar scaffolding types. When, in reality, they are not.

Figure 6 – Image of a tube and clamp scaffolding

In this section of the FAQ guide, we’ll be discussing the distinctive factors between identifying what frame scaffolding is from tube and clamp scaffolding.

Frame scaffolding is one of the many different types of scaffolding that is comprised of various platforms that are supported on fabricated end frames. In complementary to this, frame scaffolding also utilizes horizontal bearers, integral posts, as well as other accessories and members.

Tube and Clamp Scaffolding, on the other hand, is a type of scaffolding that’s comprised of steel tubes and pipes, different types of clamps, as well as other accessories.

To compare them even further, here is a quick table for your reference:

| Frame Scaffolding | Tube and Clamp Scaffolding |

| Easy to erect, establish, and dismantle since it only requires too few components. | Difficult and challenging to erect and remove. |

| Strong but not as strong as that of tube and clamp scaffolding. | Contains a lot of different types of couplers and clamps, making the construction effective. |

| The total assembly height would be 2.5 times higher than tube and clamp scaffolding, which can be up to 65 meters high. | Overall, the height of tube and clamp scaffolding shall not be more than thirty (30) meters. |

These are some of the notable differences between tube and clamp scaffolding and frame scaffolding.

How to Choose the Perfect Frame scaffold for Your Project?

When it comes to frame scaffolding, there are a lot of things to consider. What’s the project? What’s the budget? What’s the deadline? And most importantly, what’s the weight capacity required for the job? We will help you answer all those questions and more so you can choose the perfect frame scaffold for your project.

Frame scaffolds come in a variety of sizes and styles, so it’s important to first determine the scope of the project. What is the height and width of the area that needs to be covered? How many workers will be using the scaffold at once? Once you have an idea of what you need, you can start looking at different frame scaffold models.

There are two main types of frame scaffolds: modular and traditional. Modular frame scaffolds are made up of individual pieces that can be easily assembled and disassembled, making them a great option for smaller projects or when portability is a must. Traditional frame scaffolds, on the other hand, are more durable and stable but are also harder to set up and take down.

When it comes to budget, frame scaffolds can range from small, basic model to several large, industrial-grade scaffold. Keep in mind that the price will also depend on the weight capacity of the scaffold. The higher the weight capacity, the more expensive the scaffold will be.

Finally, when choosing a frame scaffold, always make sure to check the weight limit and assembly instructions carefully. Each model has its own specific weight capacity and requirements for assembly, so it’s important to choose the right one for the job. frame scaffolds can be a great option for any project, big or small. With the right frame scaffold, you can be sure your project will be completed on time and within budget.

Where to Get High Quality Frame Scaffolding?

You’ll be able to find a lot of frame scaffolding suppliers and manufacturers in the market. But, if you’re eager to get the best and highest quality of it, better work with us here at Jumply.

For more than a decade, Jumply has been known to be the best and most reliable frame scaffolding manufacturer. Thanks to the skill, determination, and sheer will of our engineers and experts, we were able to produce and develop the best types and kinds of frame scaffolding systems for businesses and construction projects from all around the world.

The frame scaffolding we offer here at Jumply is applicable to all different types and kinds of projects, such as maintenance projects, construction, demolition, decoration, and even renovation and improvement!

Why is Jumply Your Best Choice For Frame Scaffolding?

Jumply, being China’s top pick in frame scaffolding can give you the guarantee and assurance of quality for all the types and kinds of frame scaffolding.

Here are some of the few, most relevant factors that make us the best when it comes to frame scaffolding:

- We can offer American Frame, Japanese Frame, and Euro Frame scaffolding

- All the parts and components of our frame scaffolding systems are made from high-grades of steel (even aluminum)

- Jumply can surely meet the demands you’re looking for as we offer custom frame scaffolding!

With Jumply being your frame scaffolding manufacturer, you will never experience any type of failure or mishap. Wherever you are in the world, Jumply will just be a call or an email away!

Other than frame scaffolding, you can also count on us if you need cuplock scaffolding, ringlock scaffolding, kwikstage scaffolding, and other types of modular scaffolding, too!