Cuplock Scaffolding

Jumply is top cuplock scaffolding manufacturer & Supplier in China. If you have any requirements for cuplock scaffolding system, you can contact us.

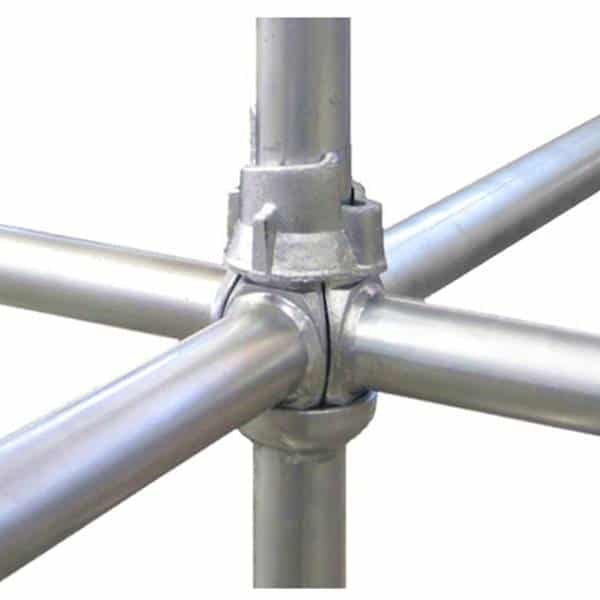

A unique node point connection allows up to 4 horizontal parts to be connected with a vertical part in once single action without the use of nuts, bolts or wedges. The locking device is formed by two cups, a fixed bottom cup which is welded to the vertical pipe at the pre-located intervals and a sliding upper cup. The blade ends of the ledger are located into the lower cup, the upper cup is moved down to secure it in place.

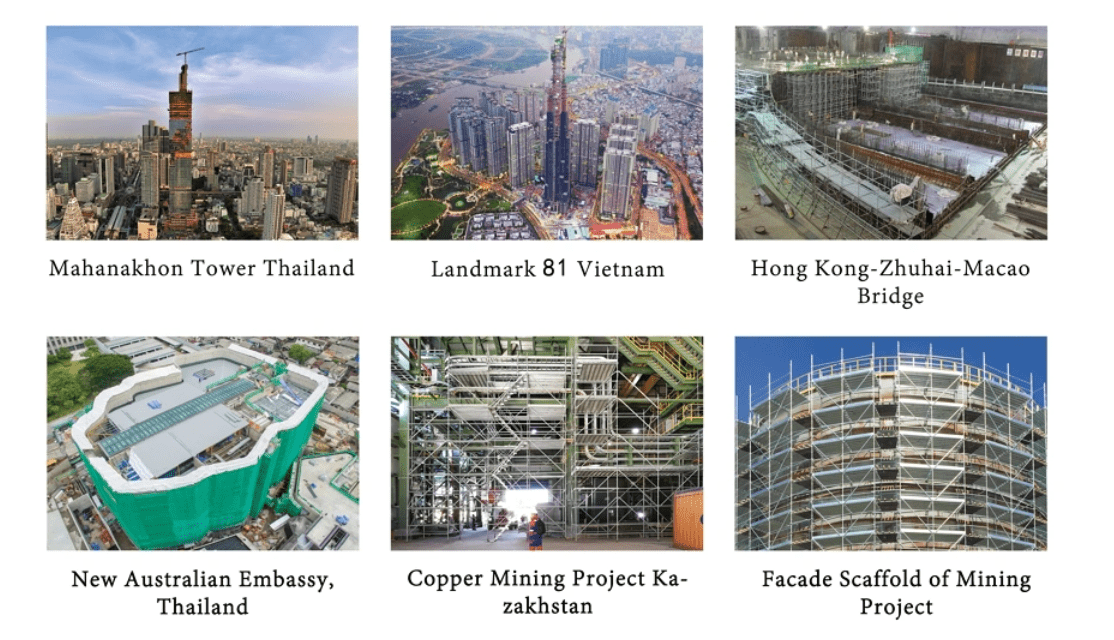

Our commitment to quality, safety, and cost efficiency sets us apart in the industry. As dedicated partners, we support clients of all sizes worldwide. Whether you need a reliable aluminum ringlock ledger or other scaffolding solutions, we are here to meet your needs with unparalleled expertise and dedication.

Our aluminum ringlock scaffolding systems are not only lightweight and durable but also adhere to the highest safety standards. These features make them the ideal choice for a wide range of construction and industrial projects. We are consistently dedicated to providing top-quality products and services, ensuring your projects proceed smoothly and cost-effectively.

Jumply Scaffolding brings extensive experience and state-of-the-art automated equipment to deliver customized scaffolding solutions, including ringlock ledger systems, tailored to meet diverse requirements.

Jumply stands for safety and quality in scaffolding, showcased through our construction projects. Experience the superior quality of our products, including our ringlock ledger systems, which we continually enhance to meet your needs.

Jumply Cuplock Scaffolding Video

Why Choose Jumply?

- High quality and economical price

- Customized standards for any work site

- Commitment to quality

- Safety and durability

- Innovations in design

- Scaffold services available 24 hours/day

- Gets EN10901 and ISO3834 accreditation

- Certifiedwork-safe scaffolding manufacturer

- Attain quality you need in your work

- Be secure when on the scaffolding

- Provide safety training

- Wide variety of scaffold expertise to suit all needs

- Scaffolds are available in a wide range of sizes

Cuplock Standard

This Cuplock Standard is perfect for all your construction needs! Its tube diameter of 48.3mm and thickness of 3.2mm make it a sturdy, reliable option that you can count on. And its galvanized surface treatment will help keep it looking great for years to come!

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q345, Surface treatment: Hot dip galvanized

| Product | Length | ||

| Code | Description | Inches | Meters |

| CLS500 | 1 Cup standard w/spigot 1′-8″ | 19.69 | 0.5 |

| CLS1000 | 2 Cup standard w/spigot 3′-3″ | 39.37 | 1.0 |

| CLS1500 | 3 Cup standard w/spigot 4′-11″ | 59.06 | 1.5 |

| CLS2000 | 4 Cup standard w/spigot 6′-6″ | 78.74 | 2.0 |

| CLS2500 | 5 Cup standard w/spigot 8′-2″ | 98.43 | 2.5 |

| CLS3000 | 6 Cup standard w/spigot 9′-10″ | 118.11 | 3.0 |

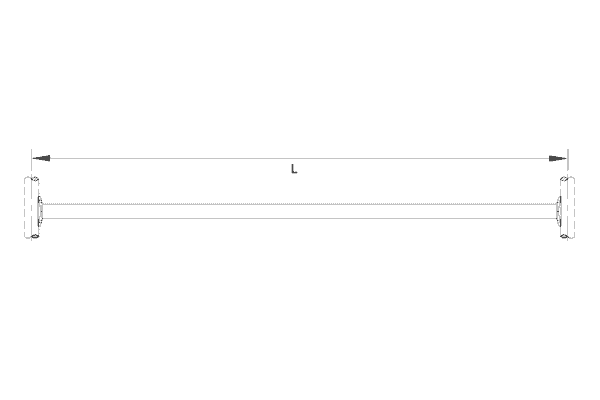

Cuplock Ledger

We have created the world’s strongest and most durable ledger! Our Jumply/Cuplock Ledger is perfect for keeping your books in order. With a diameter of 48.3mm and thickness of 3.2mm, it can withstand anything you throw at it! The surface treatment is hot dip galvanized, ensuring that it will last long and look good doing it!

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q345, Surface treatment: Hot dip galvanized

| Product | Length | ||

| Code | Description | Inches | Meters |

| CLL787 | 2′-7″ Ledger | 31 | 0.787 |

| CLL914 | 3′ Ledger | 36 | 0.914 |

| CLL1066 | 3′-6″ Ledger | 42 | 1.066 |

| CLL1219 | 4′ Ledger | 48 | 1.219 |

| CLL1524 | 5′ Ledger | 60 | 1.524 |

| CLL1828 | 6′ Ledger | 72 | 1.828 |

| CLL2133 | 7′ Ledger | 84 | 2.133 |

| CLL2438 | 8′ Ledger | 96 | 2.438 |

| CLL2743 | 9′ Ledger | 108 | 2.743 |

| CLL3048 | 10′ Ledger | 120 | 3.048 |

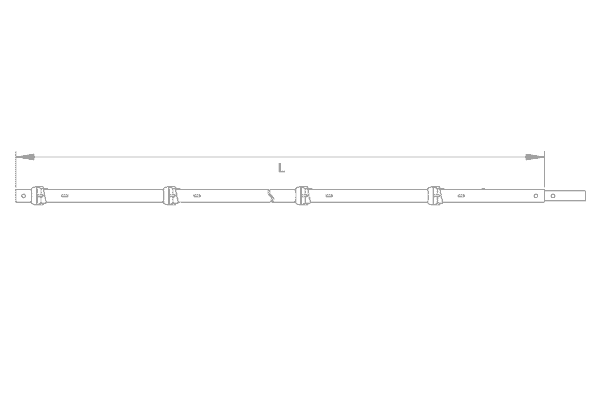

Cuplock Diagonal Brace

With a diameter of 48.3mm and a thickness of 3.2mm, this steel tube is perfect for creating sturdy ledgers. It’s made from Q345 steel and has a hot dip galvanized finish to protect it from the elements.

Tube diameter: 48.3mm, thickness: 2.5mm, Steel Grade: Q235, Surface treatment: Hot dip galvanized

| Product | Width | Length | |||

| code | description | Inches | Meters | Inches | Meters |

| CLDB2342 | 4′ Diagonal Brace | 48 | 1.219 | 78.74 | 2 |

| CLDB2514 | 5′ Diagonal Brace | 60 | 1.524 | 78.74 | 2 |

| CLDB2693 | 5′-11″ Diagonal Brace | 71 | 1.803 | 78.74 | 2 |

| CLDB2924 | 7′ Diagonal Brace | 84 | 2.133 | 78.74 | 2 |

| CLDB3153 | 8′ Diagonal Brace | 96 | 2.438 | 78.74 | 2 |

| CLDB3193 | 8′-2″ Diagonal Brace | 98 | 2.489 | 78.74 | 2 |

| CLDB3394 | 9′ Diagonal Brace | 108 | 2.743 | 78.74 | 2 |

| CLDB3645 | 10′ Diagonal Brace | 120 | 3.048 | 78.74 | 2 |

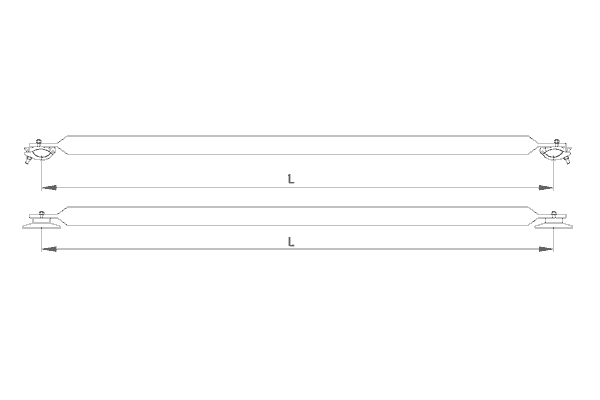

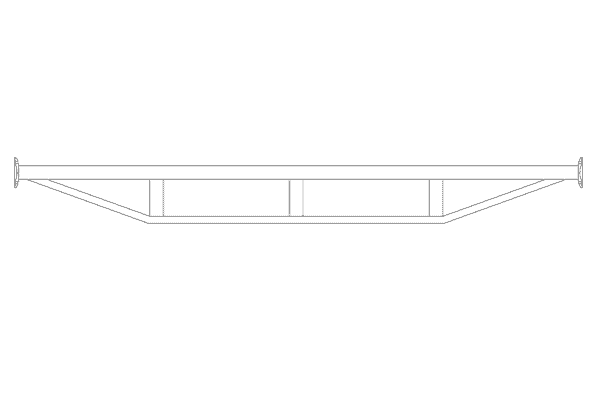

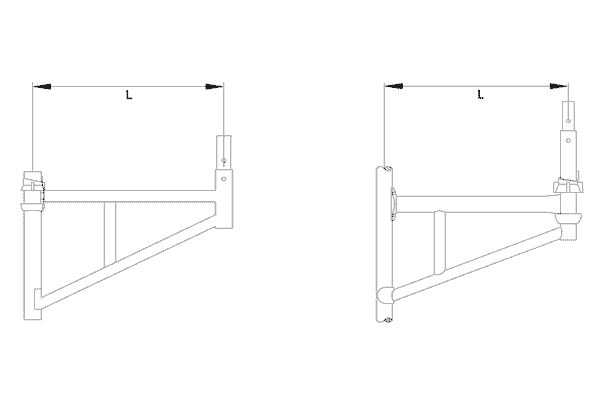

Cuplock Truss

Introducing the newest member of the Jumply/Cuplock family – the Cuplock Truss! This truss is made with a 48.3mm diameter tube and a thickness of 3.2mm, making it strong and durable enough to support any load. It’s also hot dip galvanized for a long-lasting finish.

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q235, Surface treatment: Hot dip galvanized

| Product | Length | ||

| Code | Description | Inches | Meters |

| CLT2133 | 7′ Truss | 84 | 2.133 |

| CLT2438 | 8′ Truss | 96 | 2.438 |

| CLT2743 | 9′ Truss | 108 | 2.743 |

| CLT3048 | 10′ Truss | 120 | 3.048 |

| CLT3658 | 12′ Truss | 144 | 3.658 |

| CLT4267 | 14′ Truss | 168 | 4.267 |

| CLT4877 | 16′ Truss | 192 | 4.877 |

| CLT5486 | 18′ Truss | 216 | 5.486 |

| CLT6096 | 20′ Truss | 240 | 6.096 |

| CLT6401 | 21′ Truss | 252 | 6.401 |

Tube diameter: 48.3mm, thickness: 3.2mm, Steel Grade: Q235, Surface treatment: Hot dip galvanized

| Product | Length | ||

| Code | Description | Inches | Meters |

| CLBB360 | One Board | 11.4 | 0.29 |

| CLBB390 | Two Board | 22.2 | 0.57 |

| CLBB730 | Three Board | 31.3 | 0.8 |

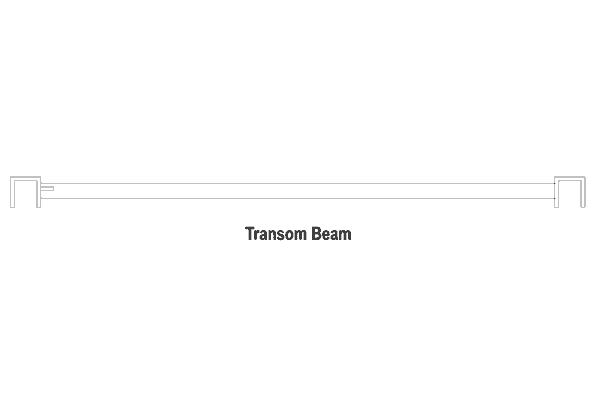

| Product | Length | ||

| Code | Description | Inches | Meters |

| CLTB914 | 3′ Transom Beam | 36 | 0.914 |

| CLTB1219 | 4′ Transom Beam | 48 | 1.219 |

Cuplock Scaffolding – The Complete FAQ Guide

Not sure where you can get the best cuplock scaffolding for your business? Can’t find the manufacturer that can help you with the highest quality of cuplock scaffolding?

If so, then you’re just on the right page! In today’s guide, we’ll be going through all the relevant information you need to know about cuplock scaffolding. We’ll be discussing everything from what it is, to what it can help you with, and of course, where you can get the best cuplock scaffolding supplies!

So, without further ado, let’s head right onto the guide!

What is Cuplock Scaffolding System?

Cuplock scaffolding is a type of scaffolding that is identified to exhibit a method of joining or fusing metal cups that lock several beams together.

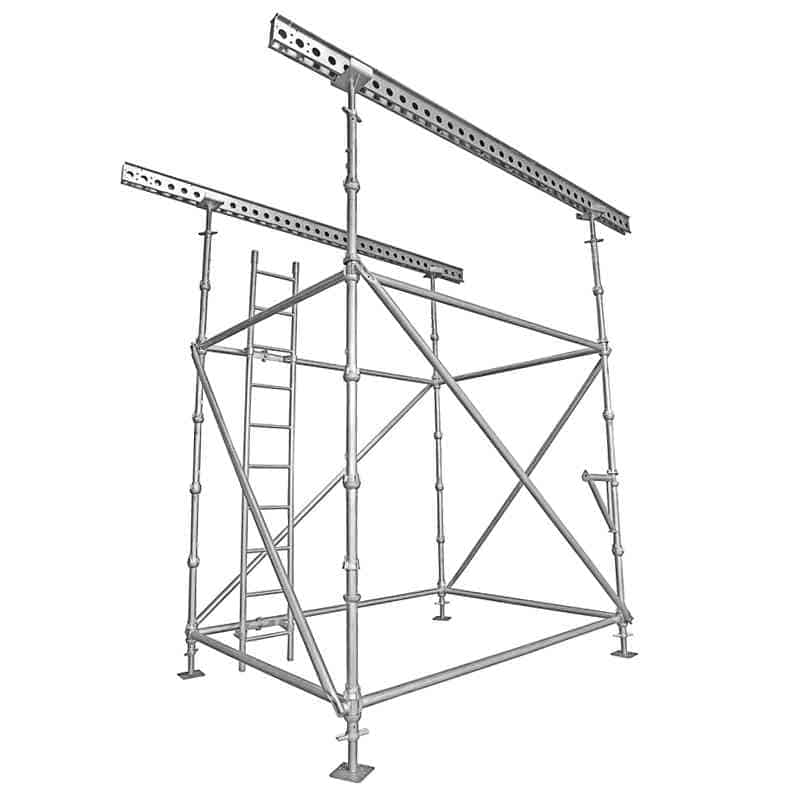

Figure 1 – Image of what a cuplock scaffold system looks like

A lot of experts consider cuplock scaffolding to be the most unique and the most flexible type of scaffolding because of its capacity of linking the beams using cups. Moreover, you will be able to use it to link and connect four (4) horizontal bars in just one (1) central joint.

What is Cuplock scaffolding?

Cuplock scaffolding is a type of construction that uses metal cups to join beams together. The distinctive cuplock system consists of three basic components: top and bottom cups, which are joined by ledger boards in between them for stability; this joint method can be easily distinguished from other types because there’s no need for nails or glue!

Who makes Cuplock scaffold?

Lyndon SGB, the manufacturer of Cuplock scaffold has been around since 1849. With over 160 years in manufacturing and design experience they are a company that knows what it takes to get things done right!

Innovative products such as their fully galvanised multi-purpose steel system called “CUPLOK” which allows jobsites easy access with tons of benefits like fasteners not being needed for connections between components due its unique node point design feature makes them stand out from all other competitors on today’s market – so if you need general purpose scaffolding or something else we can help provide exactly what your job needs then give us call because our friendly staff would be happy assist here at Jumply.

Is standard for Cuplock scaffolding?

Cuplock scaffolds are the standard for Cuperman and they have been around since 1887. The cup-lock system is made up of vertical parts, like top or bottom cups that join at an angle to form tubulars with O.D 48 mm in diameter.”

What is a system scaffold?

A scaffold is a type of temporary support system for construction work. When installing the framework, it needs to be set up in standardized bays or interlocked with cantilevers and bridges as well protection fans if applicable so that they can withstand high wind speeds without any problems at all!

What is Cuplock standard?

Cuplock standard is a great scaffolding option for work that requires the use of cup joints, such as get-in or formwork strengthening applications. The cups are at every 500mm intervals and can be moved up with ease from their inbuilt movable top plate to accommodate any rough site handling needs! These welded bottom plates made out high grade steel so they will last longer than those cheaply constructed ones you might find elsewhere on other brands’ equipment fleets – we don’t want our clients having trouble working because something broke down right when needed most.

What is the best scaffolding type?

The best scaffolding type is steel, and it’s easy to erect. Steel tubes set into each other by metal fittings or couplers make this material strong enough for even the most demanding projects with less maintenance than wood or aluminum frames can offer you too! It also provides better durability which means that your investment will last longer than if purchased another kind of scaffold in regards time spent working on them (although not as long when compared against something like brick). And finally there are lots safety features built right into these particular materials so every day workers have peace knowing their job doesn’t put themselves at risk while doing what needs done.

What is the Principle Operation of Cuplock Scaffolding?

After learning what it is, we can therefore conclude that the operation principle of these cuplock scaffolding is made creative using node points.

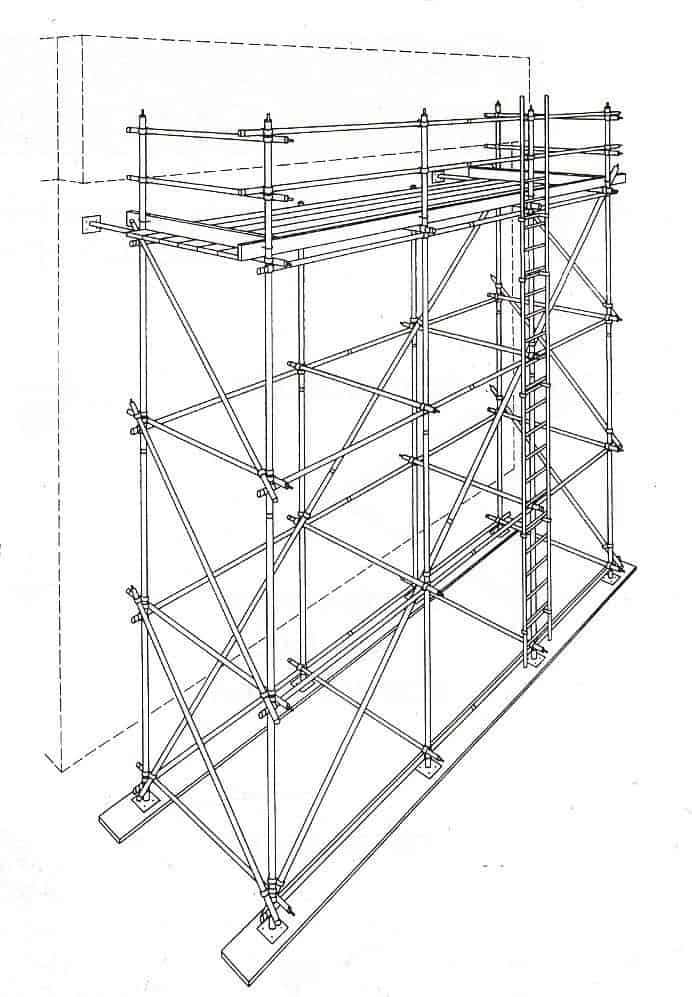

Figure 2 – The operation or working system of a cuplock scaffold

The only requirement of this particular type of scaffolding system is that the bottom cup must be welded and pre-installed before assembly. The top cup on the vertical pole at the base can be inserted into the horizontal ledger via cups made out of galvanized and strengthened steel.

What Are the Four (4) Basic Types of Scaffold?

Figure 3 – Image of what a tube and clamp scaffold looks like

While there are a lot of different types of scaffolding in the market, the four (4) basic and standard types of scaffolding include:

- Prefabricated Frame Scaffolds

- Aerial Lifts

- System Scaffolds or Modular Scaffolds

- Tube and Clamp Scaffolds

NOTE: These are only the simplest and most basic types of scaffolds in the market. There are other types of scaffolding and there are numerous ways of identifying them!

Cuplock Scaffolding Parts List

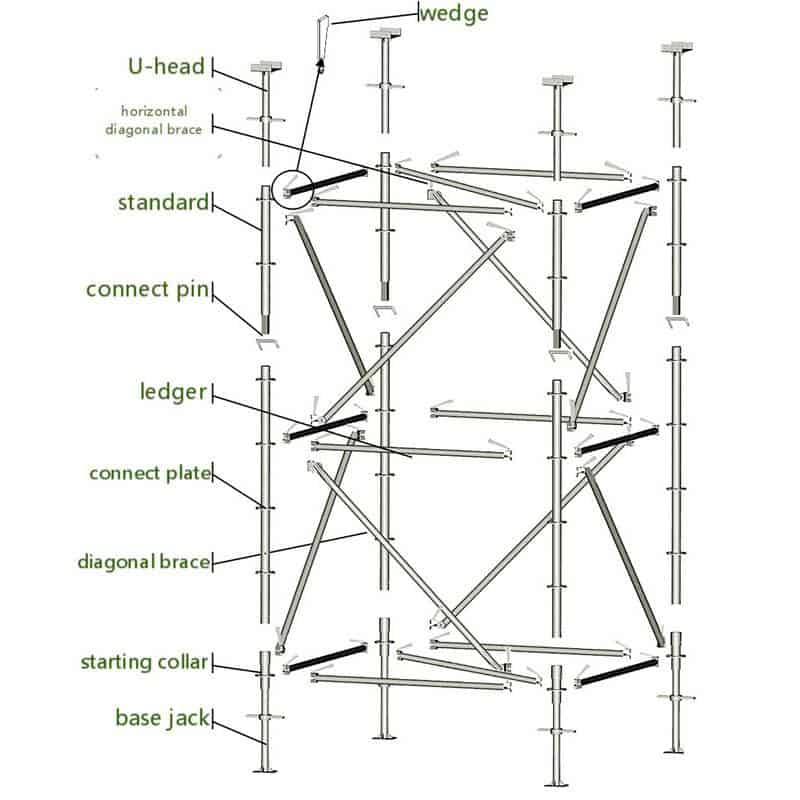

Figure 4 – Parts and components of a cuplock scaffolding system

The terminologies and labels could be different, but the parts of a cuplock scaffolding system include:

Horizontal Brace (Standard)

This is the component that runs horizontally and is responsible for connecting and linking the other horizontal braces to the vertical braces.

Vertical Brace (Standard)

This is the component that runs vertically and is responsible for connecting and linking the other vertical braces to the horizontal braces.

Diagonal Brace

Serves as additional support to the linking of the horizontal and vertical braces.

NOTE: Diagonal braces aren’t handles; this is the most common misconception that people have with diagonal braces.

Jack Base

The jack base is the foundation base or the brace that can be found at the bottom part of the cuplock scaffolding formwork.

Staircase

The staircase is the component where the workers and operators could traverse and travel up and down the scaffold.

Cups

The cups are the locking component or mechanism of cuplock scaffolding. There are several cups involved in a cuplock scaffold system, they include:

- Top Cup

- Bottom Cup

- Blade (Separator)

Catwalk

Lastly, the catwalk is the component where the workers would be able to walk around a perimeter of a horizontal base. It’s like the area where they’ll be able to change positions within the scaffold.

These are the parts and components of a cuplock scaffold. Take note, though, that how they’re called (terms) might be different from one manufacturer to another.

Cuplock Scaffolding Materials

The materials of cuplock scaffolding would depend on the available materials from a given supplier.

Figure 5 – Aluminum/steel – one of the important materials needed for cuplock scaffolding

For instance, if the cuplock scaffolding supplier only has aluminum materials, then that would be the materials involved.

Therefore, it would depend on the capability and the availability of materials. But, the materials that are used include:

- Horizontal Ledger Cuplock

- Standard Vertical Cuplock

- Brackets

- Head & Beam

- Hop-Up Brackets

- Ladder Access Transoms

Are Cuplock Scaffolding Systems Easy to Loosen?

No, they’re not! Because of the fact that they’re made from varying types of braces, they wouldn’t loosen up that easily! Cuplock scaffolding systems contain no loose fittings because of the welding and the nut installation on the cups!

How Do You Erect Cuplock Scaffolding?

Figure 6 –Image of a newly erected cuplock scaffold (final form)

The erection or the establishing of cuplock scaffolding doesn’t actually differ from other types of scaffolding. It would also start from the bottom, working its way to the top.

But, to help you understand how the process is done easier and better so you become aware of the safety and security precautions involved in it, here’s a detailed process of how it’s done:

Step 1: Assembling the Base

The first step is to assemble and attach the base. This would involve getting two (2) horizontal casters (4 braces), as well as two (2) vertical casters (4 braces).

Establish the first two (2) braces upright, and then, connect the two (2) horizontal braces to them. Do the same thing to the other side.

Step 2: Attach Caster to the Base Frame

The next step is to attach and install the caster on top of the base frame, to finish the structure of the foundation. This will require the same number of braces as you did to the base.

Step 3: Install a Diagonal Brace Below the Base

After that, complete the support base by installing a diagonal brace below the base. This should run from one side to the other side in a diagonal form to strengthen and fortify the foundation of the scaffolding.

Step 4: Add the Diagonal Brace Above the Base

To finalize the foundation, add a diagonal brace above the base, connecting the first (1st) set of casters to the second (2nd) one.

From here, you’d just have to move upward to complete the required cuplock scaffolding formwork!

It is important to note, though, that not all companies carry out the installation of cuplock scaffolding this way. This is just the standard or the regular procedure of how it’s made and structured!

Here’s a quick video of how it’s done!

Cuplock Scaffolding For Sale

Figure 7 – Image of a cuplock scaffolding being sold in the market

More often than not, cuplock scaffolding equipment and components are rented. Why? – This is because it’s never clear when you’ll be able to need these cuplock scaffolding equipment again.

However, there are certain projects where you need to purchase cuplock scaffolding equipment so you have these parts and components ready.

There are cuplock scaffolding manufacturers where you can purchase brand new parts and components. But, they might come off as expensive, especially if you don’t treat it as part of your investment.

On the contrary, you’ll be able to find 2nd hand or pre-used cuplock scaffolding for sale in the market, too! You can find them on certain websites, like that of Alibaba, eBay, and many more!

Where Can You Get the Best Cuplock Scaffolding?

The best and highest quality of cuplock scaffolding can be sourced from China. Out of all the options you have, working with Chinese cuplock scaffolding manufacturers will definitely be the best choice you’ll ever make!

But, which Chinese cuplock scaffolding supplier can you trust? It’s not unknown that China is home to some of the best manufacturing companies from regular raw materials like steel, wood, and metal – to complex and more advanced materials for tech, architecture, engineering, and yes, scaffolding!

For more than two (2) decades, Jumply has been the best and most trusted cuplock scaffolding supplier in China. Being the best and the most reliable, it’s just right to entrust to us your needs of getting a complete set of cuplock scaffolding parts, components, and materials!

Why Choose Jumply as Your Cuplock Scaffolding Manufacturer?

On a global scale, our performance in the industry remains unscathed! To give you more detail about it, here are some of the reasons why you’ll find us to be the best cuplock scaffolding manufacturer you’ll ever work with:

- We have our own scaffolding test and assessment house

- Jumply is certified and licensed to be a complete manufacturer and supplier of scaffolding equipment

- Jumply can produce scaffolding whether it’s steel, bamboo, or aluminum

- We can give you free samples of the formwork or structure of the scaffolding beforehand for free (if common)

Other than being your cuplock scaffolding manufacturing company, you can also consider us here at Jumply to be your primary supplier of scaffolding parts, modular scaffolds, octagonlock scaffolding, and many more!

Reach out to us and have a clear vision of how much budget you need for your cuplock scaffolding! Never be clueless about the budget you need to prepare for cuplock scaffolding ever again with Jumply!