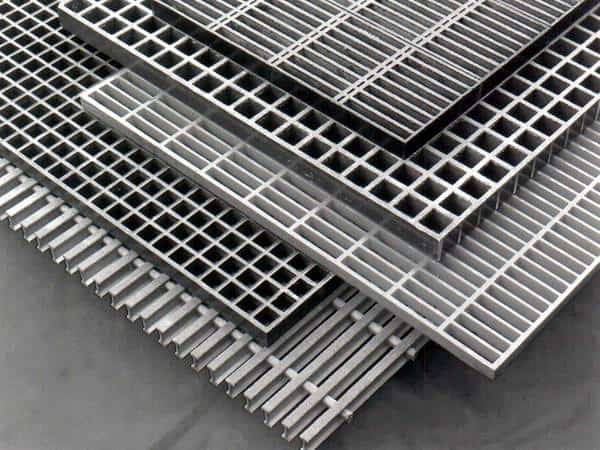

Galvanized Steel Grating

Galvanized grating is a type of steel grating that has undergone a galvanization process, which involves applying a protective zinc coating to prevent rusting and corrosion. This process enhances the durability of the steel grating, making it suitable for environments where it might be exposed to moisture or corrosive substances.

Features and Advantages

Corrosion Resistance: The galvanization process protects the steel grating from rust and corrosion, making it more durable and long-lasting, especially in wet or corrosive environments.

Strength and Durability: Despite the added layer of protection, galvanized grating maintains the strength and durability that is characteristic of steel products.

Low Maintenance: Due to its resistance to rust and corrosion, galvanized grating requires less maintenance compared to other types of steel grating.

Cost-Effective: While the galvanization process does add to the initial cost, it can be more cost-effective in the long run due to reduced maintenance costs and longer lifespan.

Safety: Similar to other types of steel grating, galvanized grating provides a slip-resistant surface that can be important for safety in many applications.

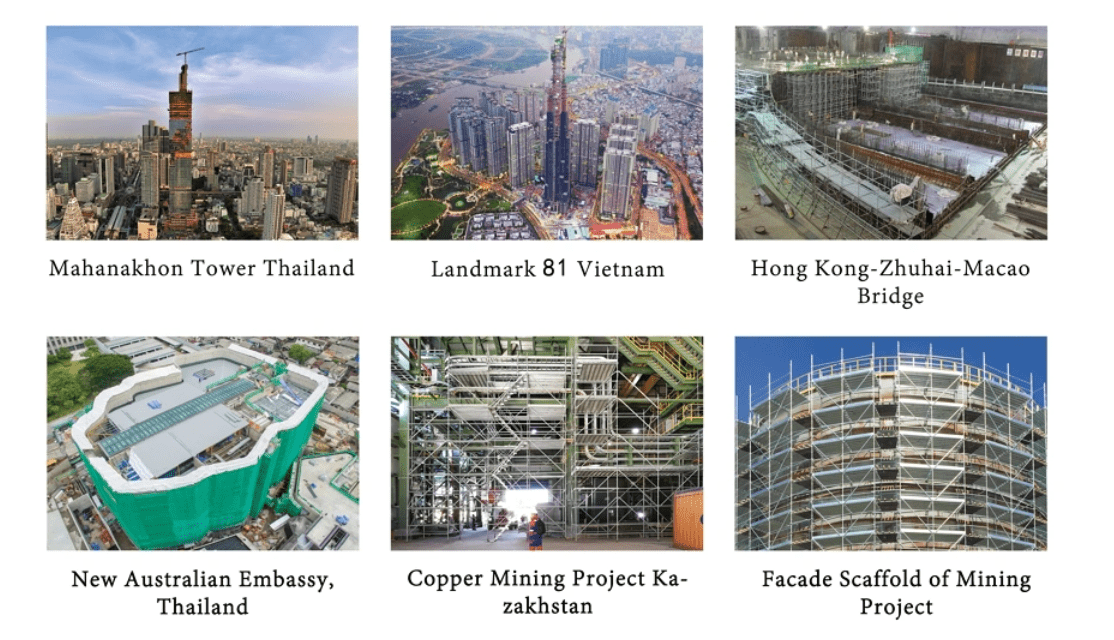

Our commitment to quality, safety, and cost efficiency sets us apart in the industry. As dedicated partners, we support clients of all sizes worldwide. Whether you need a reliable aluminum ringlock ledger or other scaffolding solutions, we are here to meet your needs with unparalleled expertise and dedication.

Our aluminum ringlock scaffolding systems are not only lightweight and durable but also adhere to the highest safety standards. These features make them the ideal choice for a wide range of construction and industrial projects. We are consistently dedicated to providing top-quality products and services, ensuring your projects proceed smoothly and cost-effectively.

Jumply Scaffolding brings extensive experience and state-of-the-art automated equipment to deliver customized scaffolding solutions, including ringlock ledger systems, tailored to meet diverse requirements.

Jumply stands for safety and quality in scaffolding, showcased through our construction projects. Experience the superior quality of our products, including our ringlock ledger systems, which we continually enhance to meet your needs.

Jumply Steel Grating

Specification

We offer a wide range of surface treatment options to cater to your specific needs. Choose from an array of finishes including Black, Hot dip galvanized, Cold dip galvanized, Painted, Powder coated, or any other surface treatment as per your requirement.

Hot Dipped Galvanized Steel Grating For Drainage: Exceptional Features and Benefits

Unparalleled Strength and Lightweight Structure: Our steel grating is engineered to deliver exceptional strength while maintaining a lightweight structure. This ensures optimal performance and longevity in various applications.

Reliable Grid Welding for Enhanced Load Bearing: The grid welding technique employed in our steel grating ensures outstanding load-bearing capacity. You can rely on our grating to handle heavy loads and provide a secure platform for diverse industrial purposes.

Advantages of a Light Structure: The lightweight nature of our steel grating offers distinct advantages, especially when it comes to hoisting operations. Its manageable weight makes installation and handling easier, saving time and effort during construction or maintenance activities.

Artistic Contour and Long-lasting Durability: Our steel grating not only excels in functionality but also boasts an aesthetic appeal. The carefully crafted contour adds a touch of artistry to your projects while ensuring durability against harsh environmental conditions. You can rely on our grating to withstand the test of time without compromising its visual appeal.

In summary, our Hot Dipped Galvanized Steel Grating for Drainage combines high strength, a lightweight structure, reliable load-bearing capabilities, an artistic contour, and exceptional durability. Experience the perfect blend of performance and aesthetics for your industrial and construction needs.

| No | Item | Description |

| 1 | Bearing bar | 25×3,25×4,30×3,30×4,30×5,32×5,40×5,50×5,…..75x10mm |

| 2 | Bear bar pitch | 12.5, 15, 20, 23.85, 25, 30, 30.16, 30.3, 34.3, 35, 40,41,60mm. US standard: 1″x3/16″, 1 1/4″x3/16″, 1 1/2″x3/16″, 1″x 1/4″, 1 1/4″x 1/4″, 1 1/2″x 1/4″ etc. |

| 3 | Cross bar pitch | 40,45,50,76,100,101.6mm etc |

| 4 | Material | ASTM A36,A1011,A569,Q235,275 |

| 5 | Surface treatment | Black, hot dipped galvanising, paint |

| 6 | Standard | China: YB/T 4001.1-2007 |

| USA: ANSI/NAAMM(MBG531-88) | ||

| UK: BS4592-1987 | ||

| Australia: AS1657-1985 |

What is Steel Grating?

Steel grating is a type of industrial product made of steel bars and cross rods. It’s usually used in industrial and commercial applications due to its high strength, light structure, durability, and convenience for loading. It’s typically manufactured through a process of welding, pressure locking, or swage-locking.

There are several types of steel grating:

-

Welded Steel Grating: This is the most commonly used type. It is produced by electrically welding steel bars to a cross rod, forming a matrix of load-bearing bars.

-

Press-locked Steel Grating: For this type, notches are made in the load-bearing bars, which are then locked together with cross rods under high pressure.

-

Swage-locked Steel Grating: Here, the cross rods are mechanically locked to the load-bearing bars.

Steel grating has a variety of uses, including but not limited to:

- Industrial flooring and stairs: Provides slip resistance and durability.

- Drainage covers: The open grid structure allows for easy water drainage.

- Ventilation grilles: Allows for air circulation while preventing large objects from passing through.

- Fences and handrails: Provides sturdy and secure boundaries.

- Platforms: Can support heavy loads, providing a durable surface for industrial platforms.

The major advantages of steel grating are its strength, its high load-bearing capacity, its versatility, and its relatively easy installation process. However, it requires periodic maintenance to prevent corrosion, particularly in outdoor environments or corrosive industrial settings. It can be coated or galvanized to help reduce this issue.

Applications

Galvanized steel grating is widely used in various industries and for various applications, thanks to its enhanced durability and resistance to corrosion. Some common applications include:

Industrial platforms and walkways: Galvanized grating is often used for flooring in industrial environments where the grating may be exposed to corrosive substances.

Drainage Systems: Its corrosion resistance makes it ideal for use in drainage covers that are exposed to water and outdoor elements.

Stair treads: Used in industrial settings, offering durability and slip-resistance for safety.

Fences and barriers: For security and safety in various environments.

Bridge decks and Docks: Due to its durability and resistance to environmental conditions.

The Hot Dipped Galvanized Steel Grating For Drainage finds extensive applications in various industries and infrastructure projects. It is widely utilized in power plants, chemical plants, refineries, iron and steel plants, paper mills, machine factories, cement plants, municipal engineering projects, sewage treatment plants, and environmental sanitation projects. The grating serves multiple purposes, such as platforms, aisles, trestles, ditch lids, well lids, ladders, railings, guardrails, and more.

With its exceptional durability and functionality, this galvanized steel grating provides reliable support and safety in industrial and construction environments. It offers a robust and secure platform for workers, allowing them to navigate and access different areas efficiently. Moreover, the galvanized coating enhances its resistance to corrosion, making it ideal for demanding and harsh environments.

Whether you require a stable platform for power generation, a safe walkway in a chemical facility, or a durable cover for drainage systems, the Hot Dipped Galvanized Steel Grating For Drainage is the perfect solution. Experience its versatility and reliability in various applications, ensuring the smooth operation of your infrastructure projects.

FAQ

Our steel grating comes in various sizes, grades, and types. We offer welded, press-locked, and swage-locked options. Our products are designed to meet different load-bearing capacities. We use high-grade carbon steel, stainless steel, and galvanized steel in our construction.

We follow ISO 9001 quality management standards strictly and have rigorous quality control measures in place at every stage of our manufacturing process, from raw material sourcing to final product delivery.

Our pricing is competitive and depends on the type, size, and quantity of your order. We do offer discounts for bulk orders. We’d be glad to provide you with a quotation upon request.

Shipping costs depend on the destination and the size of the order. Our products are securely packaged to ensure their safety during transport. Shipping duration varies but we always strive for quick and efficient delivery.

As the buyer, you would typically be responsible for any import duties or taxes. However, we can provide you with the necessary documentation to help you calculate and understand these costs.

We provide a warranty on our products to cover any manufacturing defects. The duration and coverage of the warranty depend on the product type. Our after-sales service team is also ready to assist you with any concerns or issues you may have.

Our products meet various international safety and quality standards. For example, we comply with CE marking for the European Economic Area and ASTM standards for the United States. We can provide certification documentation upon request.

Yes, we do provide sample orders to give you a better understanding of our product quality. Please get in touch with our sales team to arrange this.